2019/03/13 - I've pulled this post/project out of the "birds" topic and created a new one to serve as an archive because it:

- had just grown:

-- too unwieldy

-- mostly irrelevant with respect to its original home

- really needed one

Contact - TadErcksn - at - aol - dot - com

---

Had been wanting to write an article on / operator's manual for my spotting scope system, most of which will be relevant to any spotting scope system. The article evolved into a book as I continued testing, experimenting, learning, better understanding the issues and developed, edited, expanded on, rewrote it. Major BITCH to get/keep all these interrelated issues concise, nonrepetitive, accurate, logically organized, reasonably properly illustrated, nonrepetitive - worked on this sucker pretty steadily for a week and a half. Read, skim, ignore it as you like.

---

What we're doing with a spotting scope is pretty analogous to what a hunter is doing with a rifle scope. We have a target upon which we're attempting to get centered, stable, focused as quickly and efficiently as possible. But we don't have to worry about and adjust for gravity and crosswind. And our target doesn't need to worry about and adjust for us.

I've attempted to optimize equipment and procedures for safety, speed, efficiency. Good news... If we're optimizing for one we're pretty much also automatically optimizing for the other two.

---

Probably initial Edition One effort times two as of this 2018/08/18 01:30:00 UTC version.

---

2020/03/30 - Ran over the post length limit of a quarter million characters.

Reset to three hundred thousand.Your message contains 250194 characters. The maximum number of allowed characters is 250000.

---

2021/02/07 - Reset to 350000.

---

2021/07/01 - Unlimited.

---

2022/07/23 - As I use, amend, modify, practice with, replace elements of this gear this document is near constantly being revised. Recommend reviewing relevant sections before acquiring gear and/or implementing procedures.

---

2023/05/10 - This document had devolved into a patchwork junk heap with no shortages of errors and inconsistencies and I'm currently working on a massive overhaul.

---

2023/06/01 - Things now in reasonably fair shape.

---

Note that I'm right handed and running and describing procedures with that bias. So feel free to swap terms whenever appropriate. (Also note that we're dealing with items of asymmetrical equipment very probably designed with such biases.)

---

For dimensions we'll use the convention: width x length x height

----------

Elements - Order of Discussion

2020/02/01 - This document has now undergone nearly eighteen months worth of edits, amendments, corrections, revisions and has long been in need of a fundamental restructuring. I originally started from the top and worked my way down but we build, assemble, set up from the foundation up. So I'm doing a flip; starting with the tripods and heads that aren't even designed, manufactured by Swarovski; working up to the glass; better ordering of discussions of offshoot issues.

At the end of this document there's a rudimentary table of contents / index which can substantially aid in navigating through and around in it.

----------

The Mission

---

2023/08/08

I recently returned from a (rather grueling) couple weeks of a Naturalist Journeys guided tour of the Pantanal - two guides, ten clients. I noticed there were three flavors of clients - all armed with binocular:

- Binocular only - six

- Binocular and Serious Camera - three

- Binocular and Scope - me

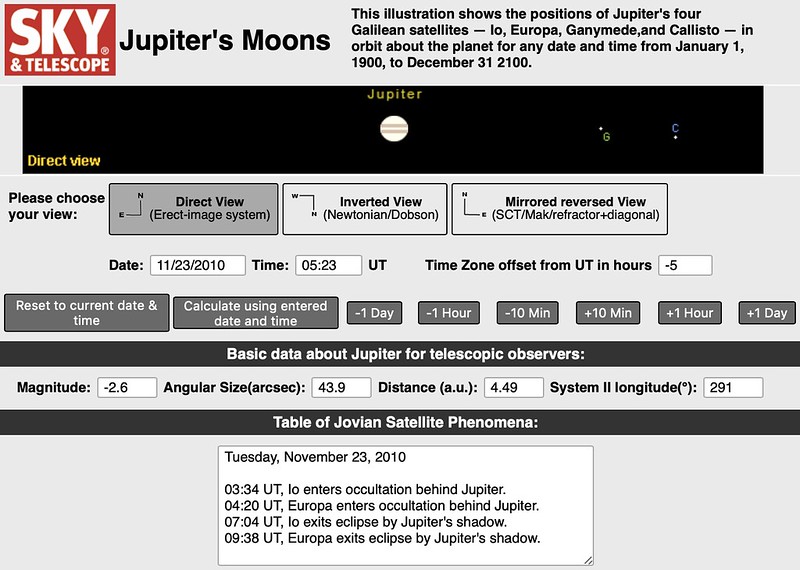

The two guides were Binocular and Serious Camera. And at least one of them was doing a lot of shooting to document and advertise the trip for the company. They had a Scope setup but my Swarovski ATX 95 / Feisol UA-180 rig was the more effective weapon and was going with me everywhere scopable and theirs saw almost zero action. I never even got the opportunity to check it out. The cameras were all handheld.

The photography has a totally legitimate and extremely valuable place but those guys are paying prices in terms of experiencing the moments. What I really enjoy is locking up quality and high value targets - wildlife and astronomical - and getting others on them. The reaction is virtually always "WOW!" And that included the photographers. On the rare occasions when they'd shot their fill of a bird I'd get them on it behind the Scope and hear the same "WOW!" I'd get from everyone else.

My point... Pick one - or alternate between two. But don't buy into the digiscoping scam - the way I did about a year into the game.

----------

Backup Loops

First let's take a look at some of the industry standard junk we need to eliminate, neutralize, work around in order to work safely, effectively, efficiently.

One of the most moronic ideas to emerge from the sport/cesspool of hang gliding is that the most disproportionally and ridiculously overstrength component of the aircraft - the hang loop (or strap) - might fail under load so we needed to have a slightly longer one installed at or near the same point to flutter in the breeze and degrade performance for the duration of the flight just in case. But wheels were - and are - for fags incapable of executing perfectly timed landing flares in all circumstances and conditions.

And as pilots we're supposed to be preflighting our birds after setting up and prepping for getting airborne. And if we're incapable of detecting an issue with this rather blindingly visible and simple a component we most assuredly lack the competence to do much of anything else related to the pursuit of this discipline.

And the optics game is well loaded with moronic crap like the backup loop which:

- addresses nonexistent issues

- degrades operating efficiency

- increases:

-- weight

-- expense

-- problematic and time and effort wasting operational issues

-- dangerous distractions

----

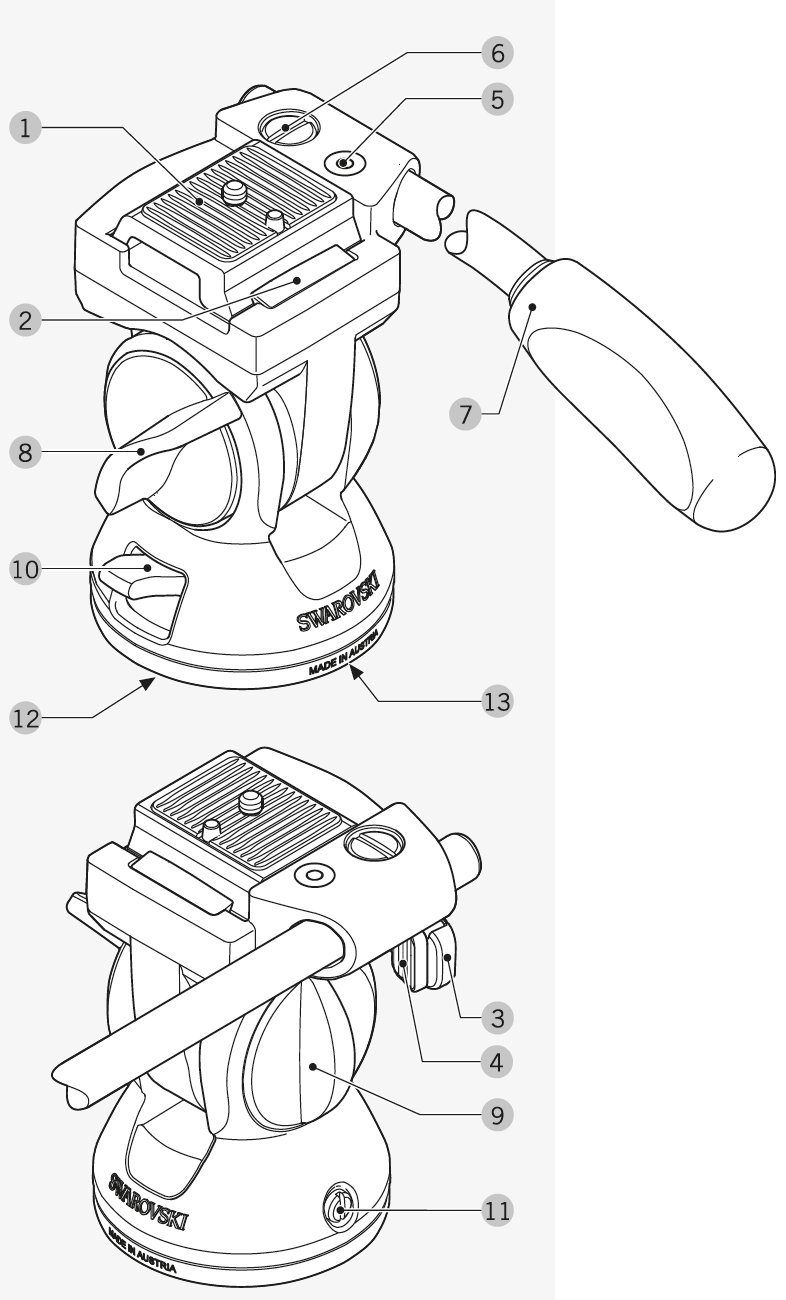

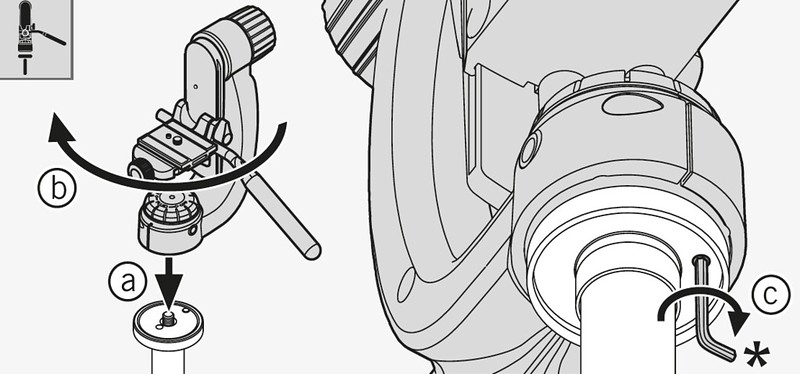

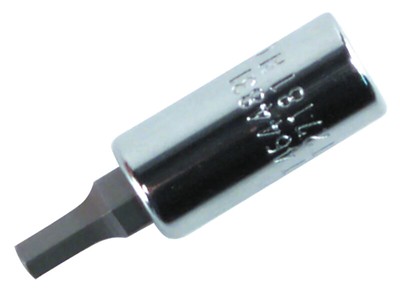

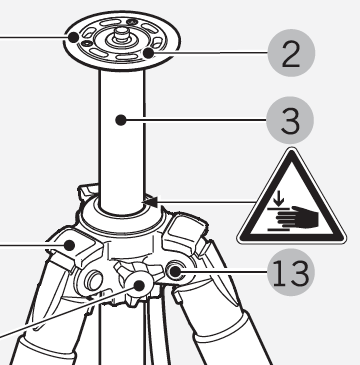

- Tripod Connection Plate Set Screws

Our Swarovski/Velbon CT101 and Swarovski/Gitzo PCT Tripod Connection Plates feature Set Screws driven from below to engage and immobilize the base surfaces/plates of Tripod Heads. THEY DON'T. They and the same on all similar gear are all placebo garbage and the folk who include them in their designs (damn near everybody) are quacks. We lock the Head onto the Tripod by torqueing it onto the Mounting Stud. And we prevent the Head from backing loose by setting panning resistance to something reasonable - just a bit over the max we want for panning to target - for torqueing on. And if we fail in those procedures it's not the least of a BFD as far as safety is concerned and the only thing Set Screw contacts will do is mar the base surfaces of Heads while they're being inadvertently or deliberately backed off. We see that effect here:

http://www.youtube.com/watch?v=6itWfnucOV0

01-00918

on this otherwise pristine and supposedly just-out-of-the-box copy being used by Swarovski for its PTH instructional/promotional video. And that marring was caused by Hans and/or one or more of their other pros having deliberately separated the Head on one or more occasions without remembering to first back off the Set Screw.

And why bother getting a pristine one out of a box for the shoot... They all look like this after the first or second trip to the field. This is totally normal.

Note that the scoring pattern is a pretty good match for the three Set Screws on their (Velbon's) rather chintzy CT101 Tripod's extremely chintzy Connection Plate - which we can see and identify in the video just fine. And that tells us that these Swarovski pros are buying into this Industry snake oil just like everybody else.

And we'll note the rather conspicuous absences of anything to do with installing their "SWAROVSKI OPTIK PTH professional tripod head" on their CT101 tripod and properly torqueing up the latter's Set Screws on Swarovski's "Video Tutorial Set up and features of the SWAROVSKI OPTIK PTH professional tripod head" instructional video. But don't worry... There's a breathtaking sequence on the installation of the Handle (which I tend to never use) that makes up for these voids ten times over.

Pull these things and stow them in the gear bag or find them new homes nowhere near any optical equipment. Don't just back them out generously leaving only a snowball's chance in hell of some Good Samaritan remedying your regretful oversight.

Minus the Set Screws the worst that happens is that we back off the Mounting Stud or from the Mounting Stud thirty degrees. Then we can lock up panning resistance, torque the Head back on a little harder, return to operational mode after a ten or fifteen second interruption. I've done that on several occasions. Not the least of a BFD. Matter o' fact I'll go on the record to say that we SHOULD BE erring on the light side and risking unintentionally backing off a bit every now and then.

On Car Talk eons ago I remember Tom and Ray saying that we manual transmission drivers SHOULD BE stalling out every now and then - that if we're not then we're burning clutch that we shouldn't be burning. Same deal.

I've inadvertently started unscrewing a lightly torqued on head during use while panning left on several occasions. And never in the combined world histories of birding and astro has such a minor annoyance evolved into a separation - which is the obvious implication of this crap.

The only way we can damage anything as a consequence of undertorqueing is if we're still stupid enough to have Set Screws installed. And if we're still stupid enough to have Set Screws installed we'll be motivated to overtorque and that DOES increase the probability of equipment maintenance issues and damage and physical injuries.

Everything relevant on our two models:

SetScrews-CT101

http://live.staticflickr.com/65535/49666462231_e9f16929df_o.png

SetScrews-PCT-1

http://live.staticflickr.com/65535/49665920528_07743c10d3_o.png

SetScrews-PCT-2

http://live.staticflickr.com/65535/49665920283_5a4c01f7b5_o.png

Everything not associated with the CT101's Connection Plate and the 44066 Adapter Plate is driven by a 3 millimeter Allen. A 3/16 inch slotted works for other stuff.

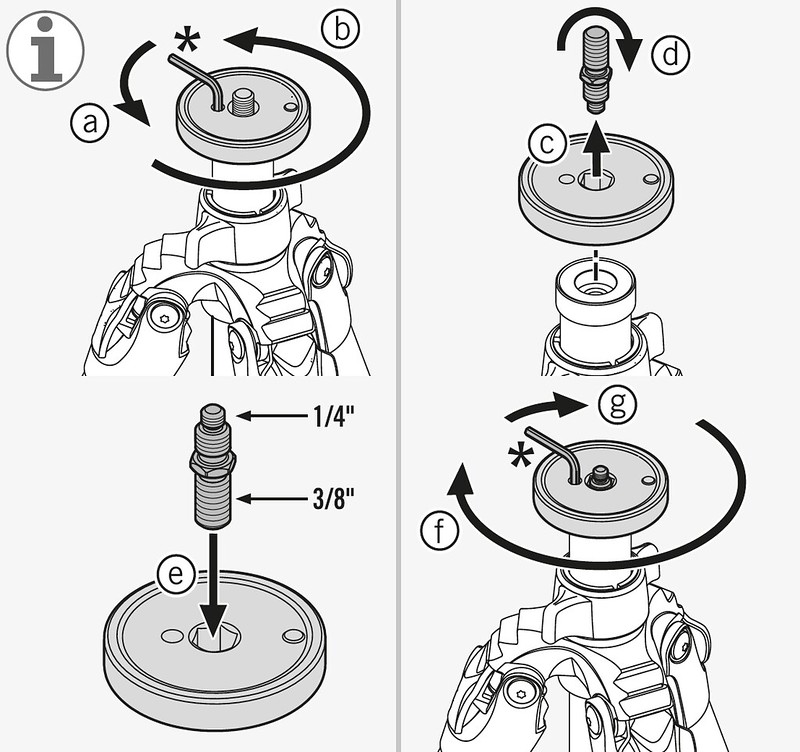

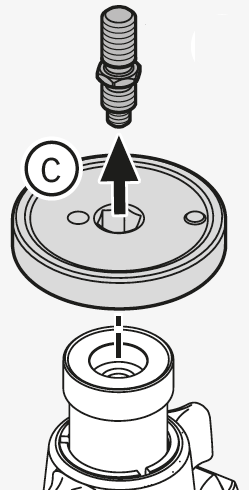

What we're seeing in the second frame of SetScrews-PCT-1 (i) above... The one Set Screw inboard, driven in and removed from above, not involved - directly anyway - in helping to prevent the Head from backing off. Its purpose is to immobilize the D0702.01 "Locking Screw" (Mounting Stud) which can be flipped to accommodate both 3/8-16 and 1/4-20 threading. If it's doing its job we can dismount our Head without risk of having to spin same a few extra revolutions due to the Insert coming with it.

If we're gonna:

- swap in a Head that takes 1/4-20 it doesn't matter in the least whether it stays with the Tripod or leaves with the Head. We need it fully disengaged anyway to flip it.

- reinstall this or swap on another 3/8-16 Head we can risk having the Insert coming off with the Head (BFD) or ensure that it doesn't by bending down and giving the Connection Plate a light clockwise twist. Versus hunting down a 3 millimeter Allen key to deal with the stupid fucking Set Screw which has already marred the little (unidentified) Cap that seats on the top of the Center Column.

Swarovski PCT

And that Little Unidentified Cap (on the Swarovski flavor only) is a total smoking gun. It's the foundation on which the three Set Screw protected components all or mostly above it - Head, D104215 Assembly Disc, D0702.01 Mounting Stud - are ultimately or directly anchored. Funny the we're suddenly able to rely solely on 3/8-16 screw torque, friction, compression at this level but not at the upper levels dependent upon it. What a load o' moronic crap.

And a real good analogy to backing up the forty G webbing that's connecting you to an aircraft that's gonna turn into swirling scrap metal at under seven Gs. But on the glider you have the option of removing the backup crap and being better than new. With Set Screws just by installing and engaging them you've already done irreversible cosmetic damage to the surfaces of whatever equipment it is that you're "protecting". And good freakin' luck consistently remembering to back off the Set Screws before starting to break the connection.

Gitzo GT3542L

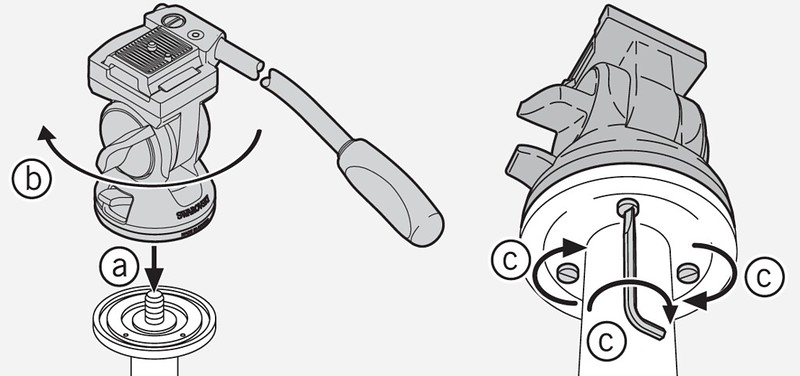

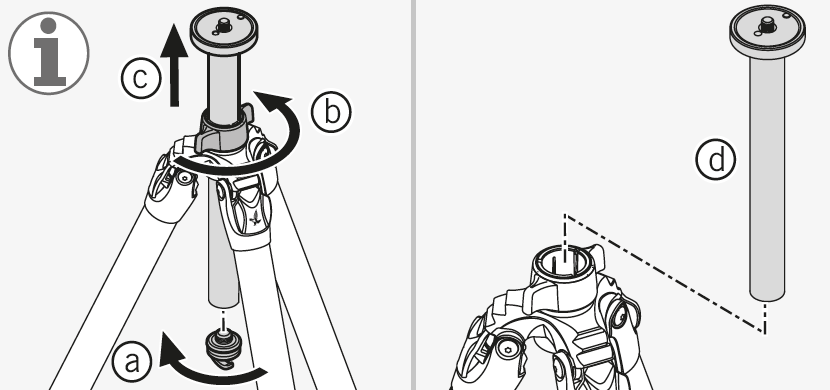

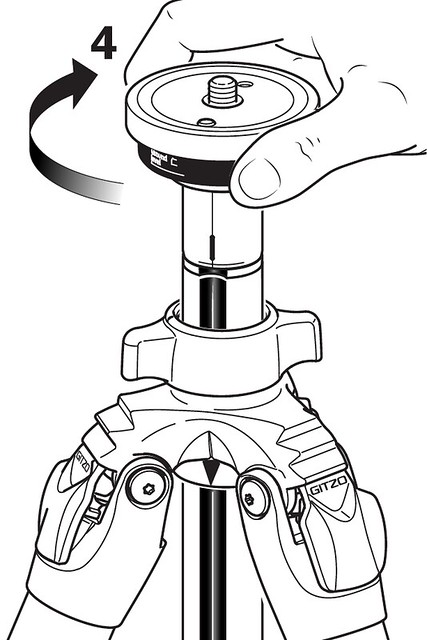

NOT SUPPLIED ON ALL MODELS?!?! So I guess the heads, cameras, scopes mounted on those models are backing off and crashing to the deck left and right. Please let us know what those models are so we can avoid them like the plague. Don't worry, I already have Feisol on my list. Hard to imagine all the carnage we're not hearing about anywhere.FIG. 4 - Fix Head on tripod

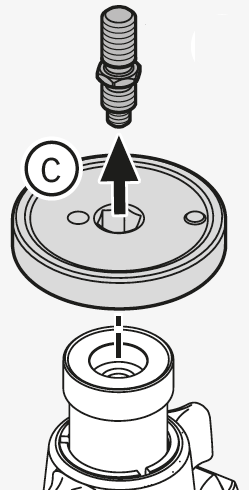

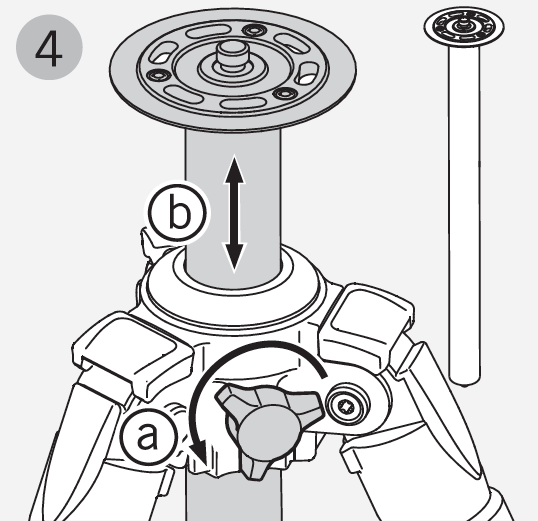

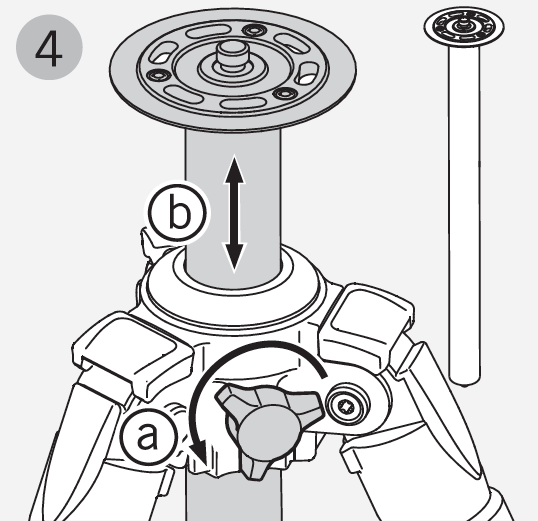

Mount the camera head on the disc at the top of the centre column (screw head clockwise).

Tighten the grub screw (not supplied on all models) against the base of the head, using the key supplied with the tripod. This feature prevents the head from unscrewing accidentally.

Head on that one is a (discontinued) Gitzo GH1780 Center Magnesium Ballhead.

And please don't show or tell us anything about about torqueing the Head on or off the Mounting Stud or making sure the Set Screws are backed off prior to separation.

http://www.feisol.net/manuals/FEISOL_Manual_CT-3342_CT-3442.pdf

FEISOL Tripod CT-3342 / CT-3442 User Manual

Wow. No set screws AND they're advising us not to over-tighten. Owners following this insane advice and stratagy must be smashing glass left and right.

For exchanging mounts (flat Ball-Head mount / Center Column mount / Leveling Base) on the tripod, unscrew the three counter-sunk screws on top of the mainframe using the included Alan key (see picture), insert desired mount and re-tighten the three screws. To avoid possible damage to the screws or tripod, please do not over-tighten them.

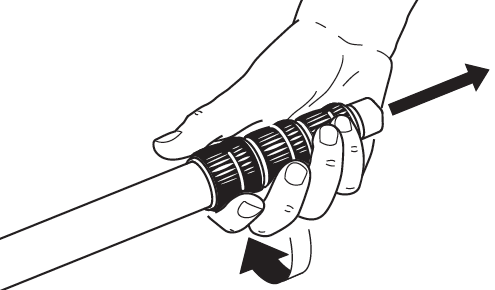

---

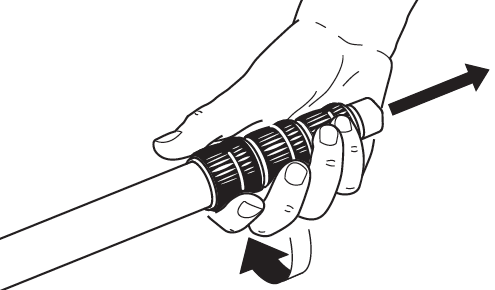

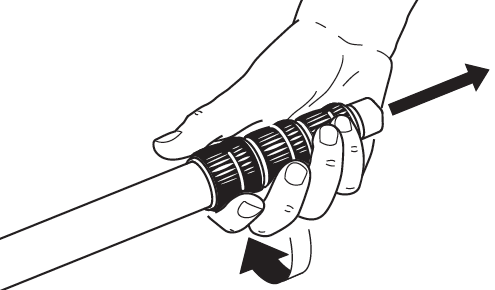

To firmly lock a leg section into place, turn the twist-lock approximately one half turn in clockwise direction. Please do not over-tighten.

---

When using the flat mounting plate (pre-installed on models CT-3372 and CT-3472), screw the Ball-Head into the mounting screw by turning the Ball-head clockwise until it fits snugly. Please do not over-tighten.

---

When using a Center Column, making sure that the Center Column is securely locked, screw the Ball-Head onto the mounting screw by turning the Ball-Head clockwise (see picture). Please do not over-tighten.

----

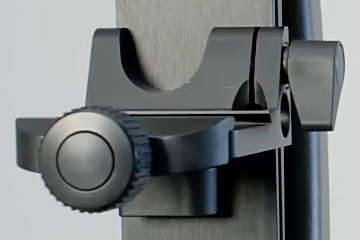

- Detent Button

02-01313

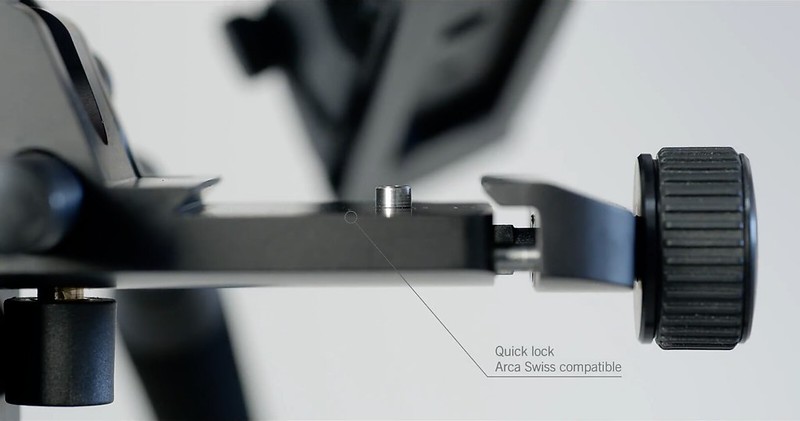

The Lens Support, we note in this shot, has a wide U-shaped cutout biased to fore and the Button is aligned with its low point. And the cutout surface is uniformly squared off from the Tilt Arm's face. 20 millimeters directly below that low/contact point on the Support's cutout we have a beveled notch such that the Button is automatically depressed when the Support is installed. Things can fall down as intended but they can't fall up minus operator intervention.

And if we WANT them to fall up while in operational mode we have to get a fingertip in between the Scope and Arm to keep the Button mashed down while we lift up on the unclamped Support - and whatever may be connected to it. And if our configuration doesn't allow sufficient clearance we'll need a popsicle stick on/in hand to do the job.

The position of the Detent Button - and implied upper safety limit - is a consequence of the Tilt Arm's mounting on the Tilt Dial and the latter's diameter.

05-03308-c

http://c2.staticflickr.com/2/1812/43116100014_cbb6caf538_o.png

Zilch to do with safety or performance. So pull the Button assembly and we have another 20 millimeters of Support travel/adjustment range up top.

As things work out our Scope tends to be pretty well trimmed for neutral at that level but who's to say we shouldn't be venturing up into the available instability range? Swarovski's DH101 and Compact Tripod Head can ONLY be operated well up into the instability range.

And the implication in both the Swarovski and Gitzo Owner's Manuals is that going above the Button isn't even an option. And rather interestingly in the Swarovski manual...

http://www.swarovskioptik.com/us/en/birding/products/accessories/spotting-scope-accessories-all/spotting-scope-tripod/professional-tripod-head#downloads

PTH professional tripod head - SWAROVSKI OPTIK

...the Button quite abruptly totally vanishes in the relevant illustration.

And speaking of vanishing Buttons... Mine wasn't always popping back out on its own after the upwards or downwards passing of the Support and required one to notice and apply a bit of agitation. Subsequently discovered that the Head had been assembled with a damaged spring. I'd been aware of this issue well before the Alaska trip and dealt with it as necessary during. But not long after I got back home... I was practicing on the backyard feeders and went to adjust from bottomed out to the top stop. 'Cept there WASN'T any top stop and the whole Scope assembly went totally and seriously airborne. I caught it like it was a bobbled ($4300 breakable) football and trapped it against the side of my head. (And I wasn't wearing a football helmet.)

I don't know how long it took for my brain to kick in enough for me to pull the assembly but I was pretty firmly locked in a mindset that the people putting this stuff together were doing everything for legitimate reasons. (Took me over two decades to pull the back-up loop off the glider I was flying.)

Button Housing - M08-1.00x5.

---

And note that on the Feisol UA-180 there are no port and/or starboard detent buttons to ensure that its Lens Support assembly and whatever glass we have mounted on don't fall up and clear to a near certain catastrophic end.

----

- Safety Stud

From Swarovski's video showing us the proper way to get glass properly and safely mounted on "their" Professional Tripod Head...

http://www.youtube.com/watch?v=6itWfnucOV0

Video Tutorial Set up and features of the SWAROVSKI OPTIK PTH professional tripod head

06-03802 - 07-03816

http://c2.staticflickr.com/2/1800/28947526087_8df2d00e0a_o.png-http://c2.staticflickr.com/2/1800/30014604428_c0aba19f43_o.png

08-03824 - 09-03906

http://c2.staticflickr.com/2/1780/28947524517_54edba8e58_o.png-http://c2.staticflickr.com/2/1799/30014603958_c342ac5735_o.png

10-03912 - 11-03914

http://c1.staticflickr.com/1/934/30014603728_d650392fbf_o.png - http://c2.staticflickr.com/2/1794/28948928777_459f8655ba_o.png

12-03918 - 13-03921

http://c2.staticflickr.com/2/1791/42981386415_9a2c8d8147_o.png - http://c1.staticflickr.com/1/932/28948928207_d1e68eeb7c_o.png

14-03924 - 15-04002

http://c1.staticflickr.com/1/933/28947523947_fbd5a094a7_o.png - http://c2.staticflickr.com/2/1817/30014603418_02f45dc181_o.png

16-04003 - 17-04007

http://c1.staticflickr.com/1/858/28947523557_b02c4000f8_o.png - http://c2.staticflickr.com/2/1814/28947523297_af63379e31_o.png

18-04116 - 19-04415

http://c2.staticflickr.com/2/1831/30014602858_80cc1547eb_o.png - http://c1.staticflickr.com/1/850/30014601448_bb5e10bfa0_o.png

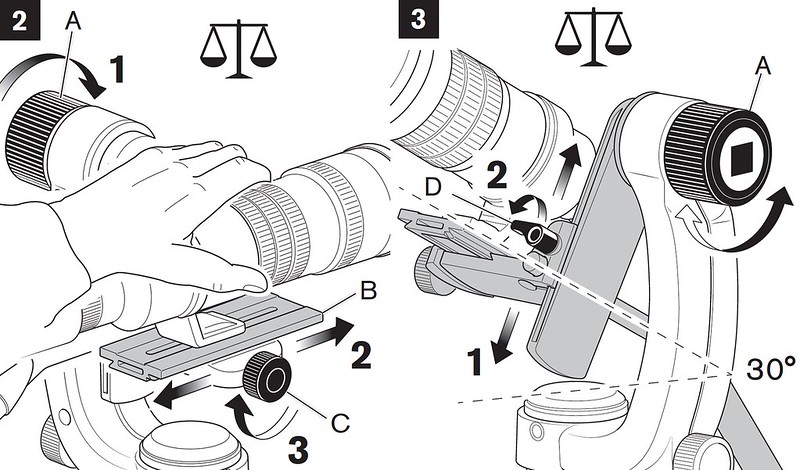

Very subtle but at 11-03914 some structure on the underside of their "Balance Rail" (plate)...

1-03401

http://c2.staticflickr.com/2/1833/43949951251_7749d8df63_o.png

...bounces off the "Safety Stud" and necessitates a minor reset. Yeah, BFD, but these are the pros showing us newbie insects how to get and do everything right. Not even worth a retake. So we should EXPECT our five thousand dollar chunk of glass to bounce back out a little for most every installation. And with enough monkeys and enough typewriters... But perish the thought that we should remove the safety feature upon which we're depending for enhanced security.

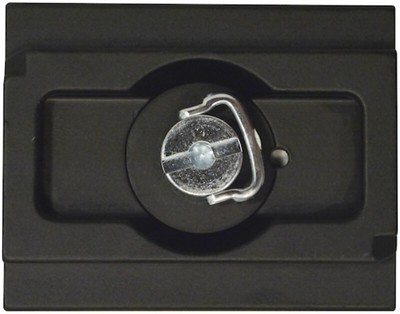

02.5 socket head cap screw, M04-0.70x05:

http://www.manfrottospares.com/

http://live.staticflickr.com/65535/50967413967_63982560a4_o.png

Swarovski 45066 Plate with the same screw serving as a Centering Stud:

http://c1.staticflickr.com/1/859/43616064242_2d9f9715b2_o.png

(If that Plate (in this obvious Swarovski studio shot) isn't configured for an ATX 65 - which is highly unlikely IMHO - it's installed BACKWARDS.)

It interferes with balance adjustments (fore/aft) for both Plates 070:

http://c1.staticflickr.com/1/941/43965137332_07b7d12e6c_o.png

http://c2.staticflickr.com/2/1815/43294926474_41bec4c70b_o.png

and 140:

Gitzo GS5370LDR Long Quick Release D Profile Plate

It prevents:

- balance adjustments for Swarovski Arca-Swiss Feet

- in a modified Clamping Channel installation of Swarovski Standard Feet

- us from deliberately sliding anything into or out of the fore or aft end of our slightly opened Clamping Channel

There will be problems we don't need to have when we're swapping glass.

We need to treat this gun as if it's always loaded and not think we can ease up on procedures a bit 'cause we have this Safety Stud (probably) installed to catch one of our lapses into casualness.

http://live.staticflickr.com/65535/49704851952_79c75b8241_o.png

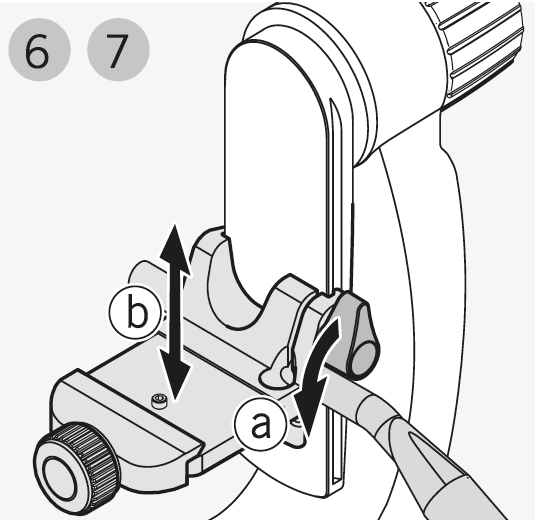

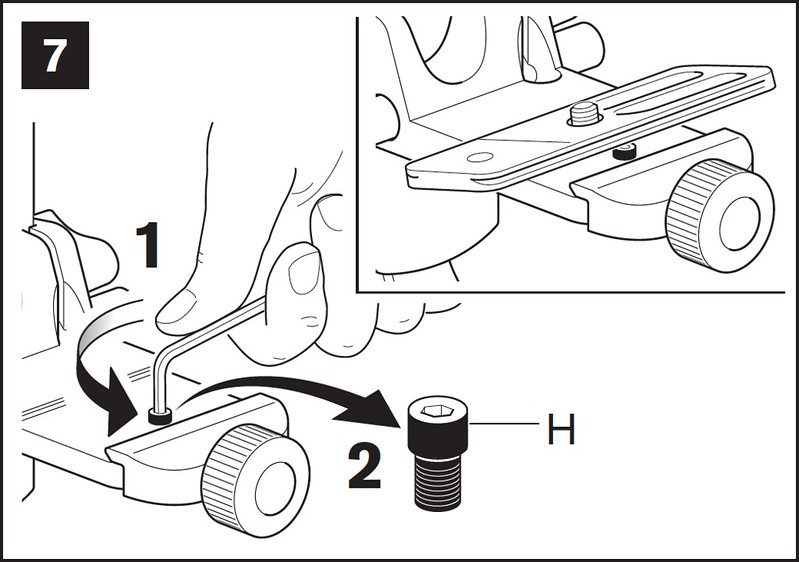

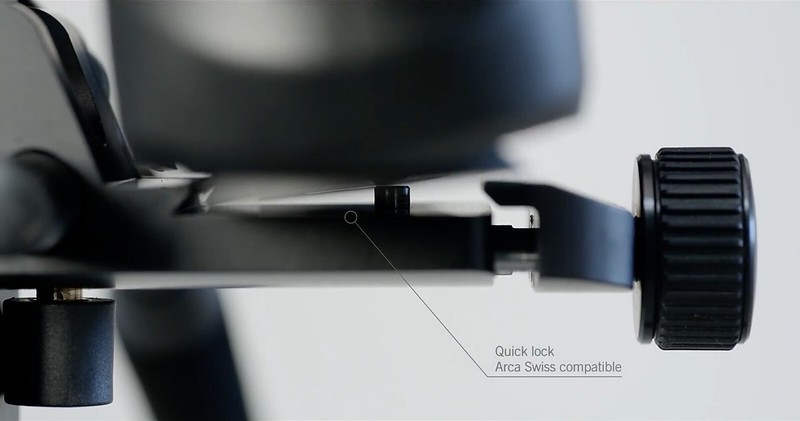

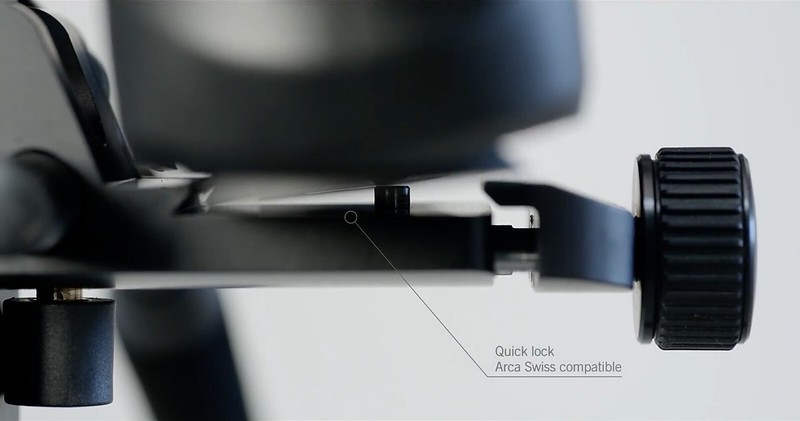

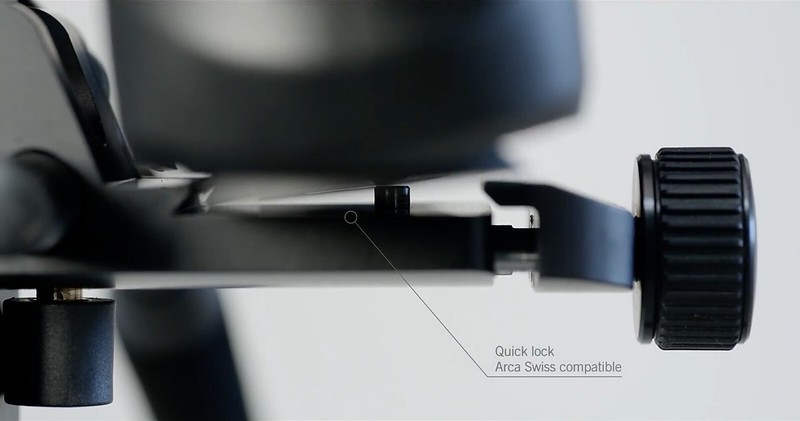

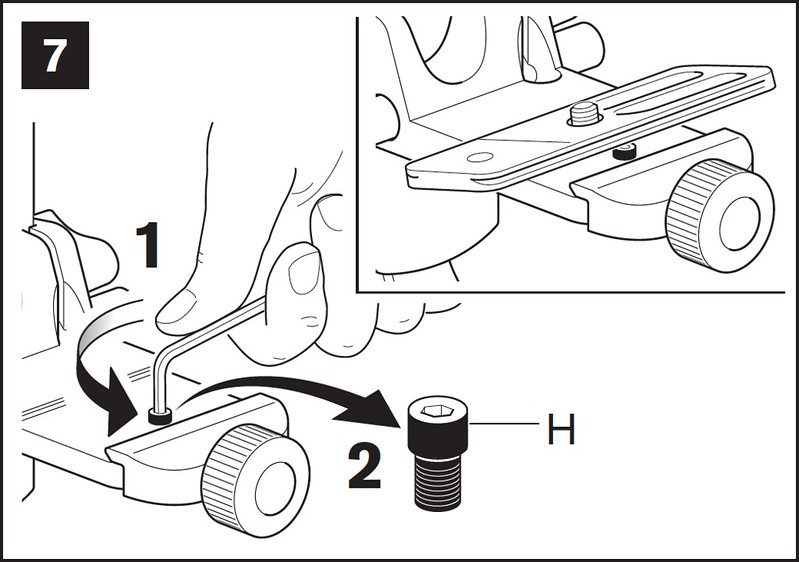

So if we DO have the safety pin installed for an assembly which can accommodate it we don't we don't need need to be as careful about clamping our glass after we have it installed in the channel? I can take this hairpin on this wet mountain road at fifty 'cause I'm wearing my seatbelt and have airbags installed?FIG. 7 - Usage with other brand plates

The Head accommodates some plates with similar dimensions. Test your plate by mounting it on the quick release adaptor. If the safety pin "H" blocks the mounting of the plate, or prevents the sliding of the plate, remove the safety pin, but take care you haven't a safety pin stop anymore!

Have you ever done any kind of survey of equipment operators to find out whether or not this crap has or could've defused an incident? Funny I've never heard so much as a recounting of a single one.

Also note that in the Swarovski flavor manual there is zero issue under any circumstances with the Safety Stud. It's a permanent element of the head assembly.

----

- Stay-On Cases

http://live.staticflickr.com/65535/52884051054_c5d6f0a736_o.png

Oxymoron. One transports glass to the field in a case. Upon arrival the glass comes out of the case, the case gets stowed, the glass gets mounted on a tripod ready to perform for an operator whose goal is to as quickly and efficiently as possible start hitting high value targets. Stay-On Cases massively cripple the operator's ability to utilize the features of his glass and quickly and efficiently operate.

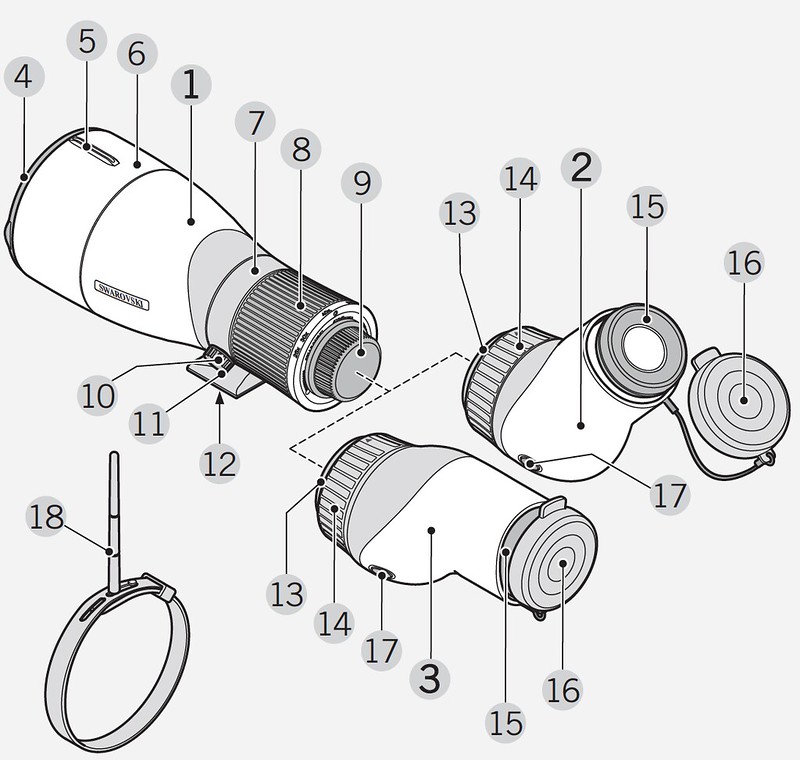

What's illustrated above is the full assembly for ATM/S 80 millimeter - Swarovski doesn't illustrate likewise for ATX - and we'll note right away that they've wallpapered over the Tripod Ring Locking Screw.

http://live.staticflickr.com/65535/49719514033_c4d6c7bd96_o.png

Might as well 'cause:

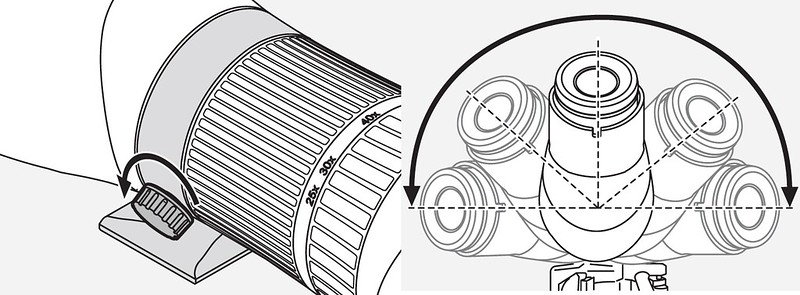

- no Swarovski Scope can be rolled off of 12 o'clock while it's being protected by a Stay-On Case

- by Swarovski and all of its Industry co-conspirators there is:

-- just shy of zero recognition that there's any capability of rolling a Scope off of 12

-- absolute zero recognition that there's ever any advantage to be gained in rolling a Scope off of 12

- this (in the ATS photo) is a Swarovski Standard (versus Arca-Swiss) Tripod Ring / Foot and the Locking Screw is barely operable under the best of circumstances

While for the ATA Stay-On Case we cover stem to stern in two elements for ATX...

85 millimeter

...(or STX) we have fore/mid/aft and the Locking Screw (Swarovski Standard or Arca-Swiss) IS accessible... But so what? Like having a switch to a light bulb that's been painted black.

And note the back end component of these Stay-On Cases DOESN'T and CAN'T Stay-On. It needs to come off and get stowed somewhere safe before we can get operational. And I can think of tons of other stuff I can put to actual use with the time and effort I'm wasting on this bullshit.

And how much thinking have we done about what Stay-On Cases are doing with respect to accessibility of our Focus...

52-053513

http://live.staticflickr.com/65535/52543133697_5f1a2b3df1_o.png

...and Zoom Collars? Not much 'cause we're a bit lucky to be remembering we have Focus and Zoom Collars while we're looking at the advertising shots.

Swarovski Scope Feet - Swarovski Standard or Arca-Swiss - are 43 millimeter length (fore to aft). My 95 (Swarovski Standard) is now used exclusively on my UA-180 Head. Its Lens Clamp length is 120 millimeters and I balance - Sunshade fully extended or with Solar Filter installed fully retracted - with about 30 millimeters of aft end and 47 millimeters of fore end clear. But for different situations I need to clamp at other positions.

Minus the Stay-On Case I can go full fore and aft without having the Scope's front end bottom out on the fore edge of the Lens Clamp. Gotta go about 13 millimeters out of the back end before I get contact.

With the Stay-On Case....

- I'm making contact with the fore edge of the Lens Clamp with about 43 millimeters of empty Clamping Channel aft.

- We lose the ability to stow the Scope with the Foot rolled up to 12 in between the Objective and the high point of our Ocular Module.

- Good luck with the:

-- rotation of the PTH's Lens Support Clamping Lever

-- stowing of your ATX with its Foot rolled up to 12

- We get a nice little three point attachment shoulder strap that I seriously doubt anyone anywhere has actually used. If I were using the Stay-On Case I'd throw the Scope in the Backpack - just as I do with LensPouches on the front and back ends with the Foot rolled up to 12 in between the Objective and the high point of my Ocular Module.

For the back end of an STX configuration:

Neither of those components is interchangeable with the corresponding ones for the ATX. (If we get things mixed up we've noted that the logo areas for the STX components are way longer than the corresponding areas for the ATX components.)

Swarovski uses as a selling point for its ATX/STX/BTX systems that they're more easily transportable because they can be broken down into their Objective and Ocular components. This is total bullshit. (Note the conspicuous absence of advisories on the downsides of transporting with the Modules assembled.) Our package packs tighter and is more abuse/damage resistant when the two elements stay bayoneted together. That configuration translates to less total volume - and that's BEFORE we start adding in the additional required packing. And instead of having four ends needing protection we have two - the fore end of the Ocular element protects the aft end of the Objective element and vice versa.

We all know we're idiots and capable of dropping onto unforgiving surfaces this expensive glass we're all trying to protect and pamper so this elegant snake oil is a fairly easy sell to someone getting started in this game. But when we're on a set we have a job to do and this crap is substantially interfering with and blocking our ability to do it. It WILL cost us:

- time:

-- setting up

-- acquiring targets

- targets we'd have otherwise nailed

If we had a Tripod Ring that left our ATX frozen at 12 and Focus and Zoom Collars that couldn't be budged at wide 09 and 03 ranges we'd send the Scope back to Swarovski for them to make good on their lifetime warranty guarantee. With the Stay-On Cases it's a pretty good bet that a few owners will never see through the scam and the practical effect will be one of permanently damaged equipment.

But - in stark contrast to the goddam Set Screws - they:

- don't physically damage the equipment they're supposed to be protecting

- are quite capable of preventing damage - in situations we shouldn't have allowed to happen

But I'm very happy with and doing fine with a:

- LensPouch on the front end for all routine activities when not targeting

- smaller LensPouch - along with the Ocular Module's Cap - on the back end for stowage and serious transport

And from all their authorized dealers:

And as a heavy user... Yeah, that aspect is pretty goddam good and effective and has zero downsides. Just not good enough when one's pitching this SOC crap.Complementing the optical performance and technologies is a lightweight and durable magnesium-alloy chassis that is wrapped in a protective rubber armor.

---

The 95 Objective Case element:

For differentiating it from the 85... Swarovski label is 41 millimeters. The lengths of the black longitudinal seams - fore edge to aft edge - for the 85 and 95 are 164 and 214 millimeters respectively. Ratios: 4.00 and 5.22 to one.

To install... Objective element goes on first. Go upside down and match the recessed area of the Case with the projection of the Foot so you can start and continue with proper alignment.

---

Component 1 is kinda cool - bottom attachment is a snap, top is a magnet, and you can rotate it 90 degrees to the side when using the Scope as a scope.

The back end boot component beats the hell outta the Ocular Module's Cap in the staying on department.

----

- Tripod Center Columns

Kinda like backup loops in that the primary item wasn't really strong/high enough to do the job properly - so we better throw on some supplemental piece o' crap. Go above and beyond the spider/apex of a tripod and we're no longer really dealing with a tripod - we start compromising the safety of our glass and stability of our image.

When I started in this game I stupidly assumed that features of industry equipment existed for legitimate reasons. We needed set screws to prevent our heads (the tripods') from backing off and falling to the asphalt with our glass engaged and center columns to extend our vertical operating range. Took me years to start realizing that center columns were absent from top notch tripods and a fair bit more to develop appropriate contempt for them.

Before I'd known and figured out much of anything my strategy for hitting and viewing high angle targets was...

- Tripod:

-- Legs:

--- fully extended

--- angled out to the first / 24 degree stop

-- Center Column extended up to about 80 percent of its capacity in order to get the back end of the Scope way the hell up

- Scope tilted way the hell up to or close to target.

- Stand straight behind the Scope.

- Tilt head (mine) back to not much shy of limit - near or to 45 degrees - in order to be able to look up into ATX's back end.

It took I-don't-know-how-long for me to stumble upon and start incorporating the technique of:

- at the waist:

-- bending down

-- twisting left

- turning my head/face formerly left / now up to look up through the ATX's back end

And...

- Feel free to substitute right for left if that works as well or better for you.

- This seems to be an issue with human wiring. I've had zillions of guests behind my glass for high astronomical targets. And quite often after I've explained and demonstrated the technique instinct will override and they go straight in behind the Scope in tilt-back mode.

- We humans are WAY better at twisting our waists and turning our heads to the left or right than we are at bending over backwards and looking straight up.

- We only need to bend and twist at the waist if the Scope's back end is a bit low. But I'm near always using low sets 'cause:

-- I'm using wide spreads of my fully extended Tripod's Legs for greater safety and stability

-- I gear and practice for sharing with guests - most of whom are lot shorter than I am

-- it's no BFD for me to use a low set even when it's down at little kid level

So no, we have zilch use for a Center Column whose only use is to get the back end up for a hypothetical boost in viewing comfort. And in the more recent past I was seeing my Center Columns as assets for the Gitzo Bubble Level installation and nothing more.

And I'm on the tall side and have been doing just fine with low sets on all normal targets and well enough even on straight-up astronomical targets.

A novice is gonna assume that when he's getting a thousand dollar Swarovski label piece of optical equipment that all the components are present for legitimate reasons and will want to utilize them and get up to competency speed. And when ya start getting up to competency speed (years later) ya start realizing that actual top notch tripods and operators don't use and incorporate center columns in their configurations. What a colossal waste of time, effort, dollars.

----

- Gitzo D0806.05 Assembly Button

Dealt with in the GT3543LS Systematic Carbon Fiber Tripod section. Massively analogous to the Gitzo / Swarovski label PTH Detent Button. Reduces the risk of the Scope assembly from falling up out of the Systematic Spider of the GT3543LS after we've backed off on the clamping.

----------

Control Axes Terms Conventions

Three control axes: pitch, roll, yaw.

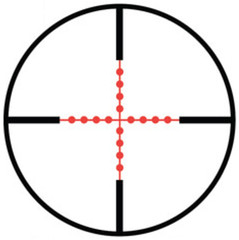

With scope stuff we're not dealing much with roll - other than with respect to rotation to position the ATX Eyepiece with respect to the tripod / horizon / observer. We're trying to get the tripod set up vertically at Square One to eliminate it from further operational equations. And we're looking at an image with a circular boundary so it tends not to be an issue within reasonable limits. And if we have a camera on the back end we tune out minor issues with the camera.

Yaw... The conventional term is pan. Dictionary definition allows yaw/horizontal and pitch/vertical - and presumably a combination of the two - to scan a scene or follow a subject. Swarovski uses swivel. We're going with pan for this document. And since the word pan is derived from panorama we're on reasonably solid ground with that convention.

Pitch... Tilt.

----------

Tripod Orientation

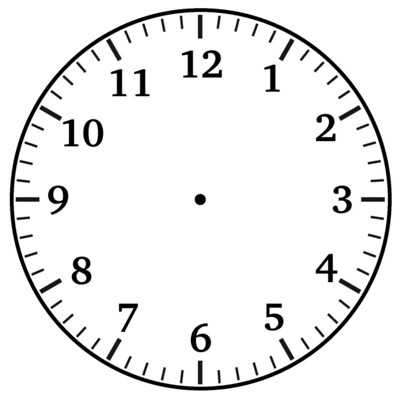

Let's name/standardize the Legs of the three Tripods based on the features on their Spiders (chassis, hubs).

- CT101

-- 02 - Center Column Clamping Lever (Knob)

-- 06 - nothing

-- 10 - eye strap into which the top end of the shoulder (carrying) strap is hooked (if we use it - which I don't)

- PCT

-- 02 - nothing

-- 06 - inside a Ridge which engages the Groove in the Center Column (to prevent it from yawing)

-- 10 - nothing

- GT3543LS

-- 02 - 3/8-16 port

-- 06 - Locking (Clamping) Knob

-- 10 - Assembly Button (below)

So our Legs are now 12, 04, 08 o'clock. (Bow, Port, Starboard would also work.)

--12--

08--04

We could also think of them as:

--NN--

SW--SE

That wouldn't be all that accurate 'cause those bearings would be:

---000---

225---135

whereas the actual bearings are:

---000---

240---120

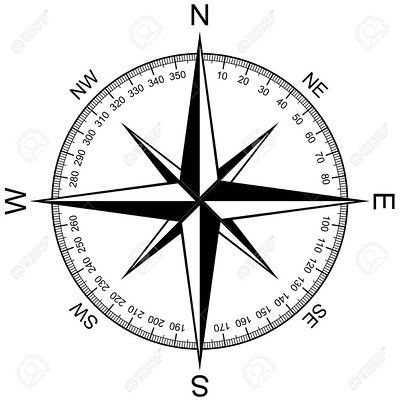

We'd be fifteen degrees too South for both. (This happens 'cause while each quarter of the clock face is next divided into thirds on the compass rose things are halved.) But let's ignore that and use North as a synonym for 12:

----12NN----

08SW----04SE

and take a look at how our numbers work:

---

Our base is a compass of 360 degrees. If it's one of the:

- eight (intercardinal level) compass points it has to be divisible by 45

- twelve clock hours it has to be divisible by 30

E-03-090, S-06-180, W-09-270, N-12-360 are the only four points which do both. (Minimum prime factorization: 2*3*3*5))

If we wanna allow half hours then we do 15 (3*5) and pick up the four intermediate compass points.

For NNE (half-wind) level resolution we have to go 22.5 (45/2 (12:03:45)).

http://www.123rf.com/photo_54708808_stock-vector-compass-rose-isolated-on-white.htm

http://illustoon.com/?id=5051

A couple tables to see/show what's going on with increments:

15 Degree / Half Hour

015 - 00:30

030 - 01:00

045 - 01:30 - NE

060 - 02:00

075 - 02:30

090 - 03:00 - E

105 - 03:30

120 - 04:00

135 - 04:30 - SE

150 - 05:00

165 - 05:30

180 - 06:00 - S

195 - 06:30

210 - 07:00

225 - 07:30 - SW

240 - 08:00

255 - 08:30

270 - 09:00 - W

285 - 09:30

300 - 10:00

315 - 10:30 - NW

330 - 11:00

345 - 11:30

360 - 12:00 - N

22.5 Degree / Compass Point

022.5 - NNE

045.0 - NE - 01:30

067.5 - ENE

090.0 - E - 03:00

112.5 - ESE

135.0 - SE- 04:30

157.5 - SSE

180.0 - S - 06:00

202.5 - SSW

225.0 - SW - 07:30

247.5 - WSW

270.0 - W - 09:00

292.5 - WNW

315.0 - NW - 10:30

337.5 - NNW

360.0 - N - 12:00

Actual orientations in hours, minutes, degrees:

--12--

08--04

--60--

40--20

---360---

240---120

---

We're gonna assume terrain with some degree of slope and/or irregularity 'cause that lines up pretty well with the real world. And our only concerns are getting the Tripod set up vertically, at max stability, and such that the back end of the Scope will or can be rolled to be at a reasonably comfortable height for a viewer. And for max stability we want our two downhill Legs - 04 and 08 - extended to the max or otherwise evenly and our uphill Leg - 12 - retracted and/or angled out to whatever degree is called for.

In order to stay consistent with our Leg designations we'll assume that all slopes face South and thus our configuration for all sets will be:

----12NN----

08SW----04SE

and bear in mind that our Tripod orientation has zero to do with our target direction. We're trying to get the assembly up vertical and at max stability and it doesn't matter in the least where or what our target or targets are or will be. But we will be standing downhill from / to the South of and facing uphill / to the North of our set while effecting it.

Note: In PCT photos the Swarovski Goshawk logo is on the Leg angle Sliding Stop for Leg 12.

It's occasionally useful to have a Tripod with everything - Legs and Center Column - fully collapsed but stood up with Legs fully spread. We'll refer to that configuration as a short set.

---

Bow - Port - Starboard could work pretty well for what we're doing.

----------

Tripod Legs Extensions

http://live.staticflickr.com/65535/32932167597_6671ffae4e_o.png

We'll designate Legs Extensions and the Extension Clamps or Twist Locks which free and lock them as 1 through 2 or 3 from the top down / largest to smallest diameter. (I've flipped this photo so the Swarovski Goshawk logo is a mirror image.)

And we'll designate fixed tubes into which the Extensions retract/collapse as Level Zero.

----------

MidHead Screws

In the various Tripod and Head components under discussion we have various screws with hex "heads" not at any end of the fastener - like most obviously:

Also:

- PTH:

-- Lens Support Clamp Mounting Stud

-- Clamp/Lock Levers:

--- pan control

--- Lens Support height

-- Handle

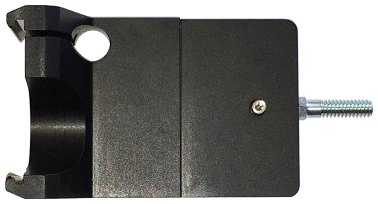

- Car Window Mount clamp

Until I stumble across an established industry term for these screw threaded fasteners I'll be referring to them as MidHead Screws. Could also be Hex MidHead Screws but that would be a bit superfluous as hex is our only option in these configurations.

The MidHead is a fair bit smaller than the heads we'd find on garden variety screws of the same diameter and pitch.

- In the illustrated 3/8-16 example the head would normally be 9/16. For the Head Mounting Stud it's two sixteenths under.

- Lens Support Clamp Mounting Stud is anchored into the base component via M06-1.00. MidHead is 07 millimeters. Standard is 10.

----------

Tripod Stability

Tripods typically feature Ballast Hooks on the bottoms of their Center Columns.

http://live.staticflickr.com/65535/49665920283_5a4c01f7b5_o.png

We can hang weight - like a backpack or bag of locally harvested rocks - to really ramp up stability and inertia and lower the hell out of the center of gravity. I've never yet been temped to give that option a go and have never yet heard of it being used in a birding application.

I've pulled the Hooks off of my CT101s and capped the 1/4-20 Screw Studs projecting from the middles of the Center Columns' (bottom) Endcaps with nylon hex nuts. Better option... Screw a 1/4-20 to 3/8-16 Adapter into a 3/8-16 nylon nut and screw that onto the Stud. Doesn't weigh anything worth mentioning, we're more likely to need the Adapter than the Hook, better protection, better for setting the Limit Stop down upright.

The Hook on the PCT is integral with the Endcap and doesn't present any problems.

---

Another stability trick I've never used or been tempted to use in the field... Install the Center Column / Head assembly in the Tripod upside down and bring your folding stool into play. (And make goddam sure the Center Column Endcap is properly and fully screwed in.)

---

On the subject... The stability of the Tripod can't be any better than the stability of the surface upon which we're set up. I've found that if I set up on the center of the back deck and continue to breathe my image is all over the place. Think trampoline. Relocating to the corner with the least ground clearance improves the situation humongously.

---

Much more on the subject but best to wait until after we've settled on a tripod and have a head, some glass, a bubble level installed. See "Uprighteousness" section far below.

----------

Swarovski Label Tripods

We'll be dealing with two of them - the now (2019) discontinued CT101 (Carbon) Tripod, introduced in 2005, depicted here...

...with the DH101 Head) and the new and much more robust and expensive PCT (Professional Carbon Tripod)...

http://c2.staticflickr.com/2/1775/43919904991_22a5bda4e7_o.png

http://live.staticflickr.com/65535/43881852322_1391176778_o.png

...which superseded it.

And they're not Swarovski tripods. They're mainstream industry tripods with Swarovski labels on them. But I didn't find that out until 2019/02 after the Costa Rica trip.

The CT101 was Velbon (http://velbon.net), the PCT is pretty much totally a Gitzo GT3542L Mountaineer Series 3 Carbon Fiber Tripod (Long).

- G - Gitzo

- T - Tripod

- 3 - Series

- 5 - Material - Carbon

- 4 - Leg Sections

- 2 - Release

- L - Long

Swarovski also does a CCT / Compact Carbon Tripod which is probably mostly a GT3542 (Not Long).

----------

Velbon CT101

Note that in a couple illustrations of the CT101...

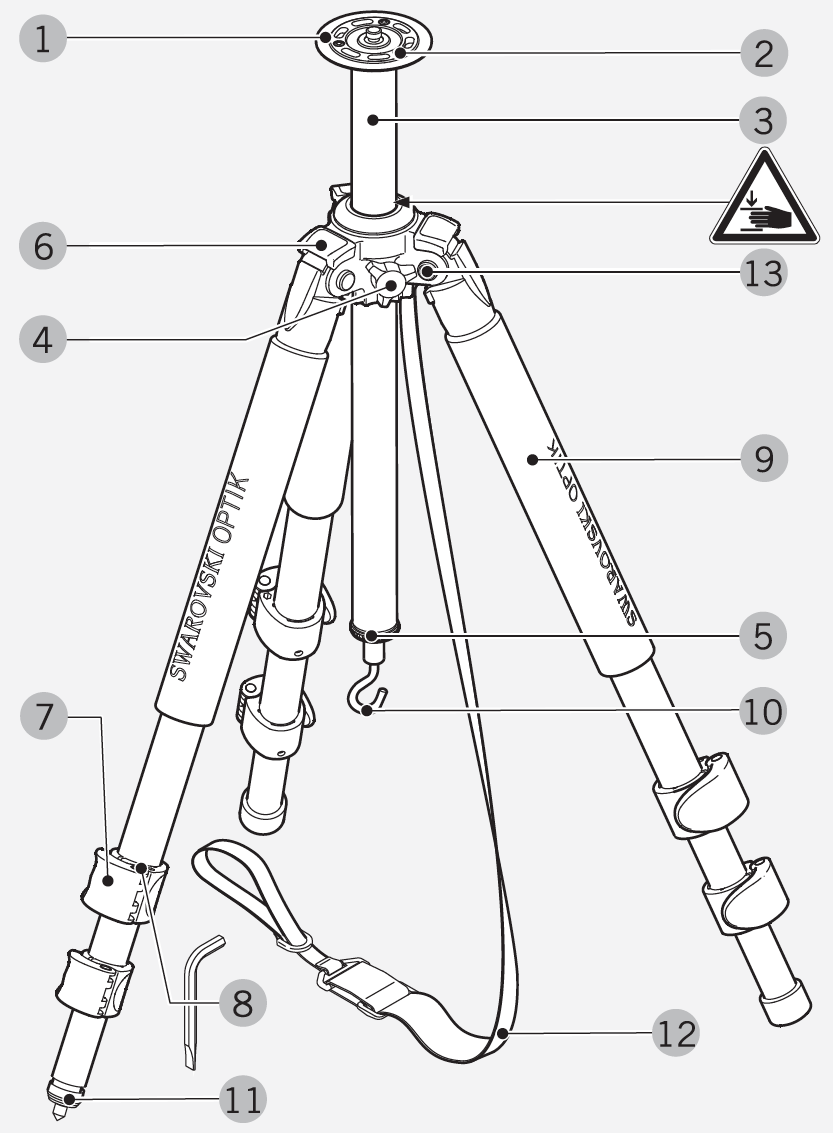

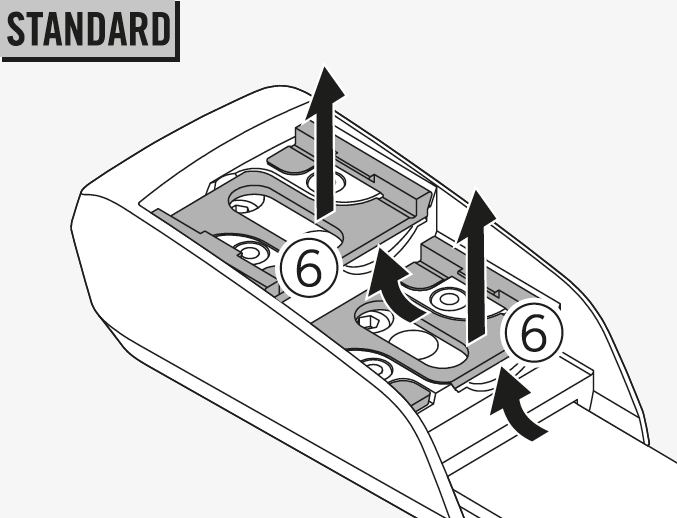

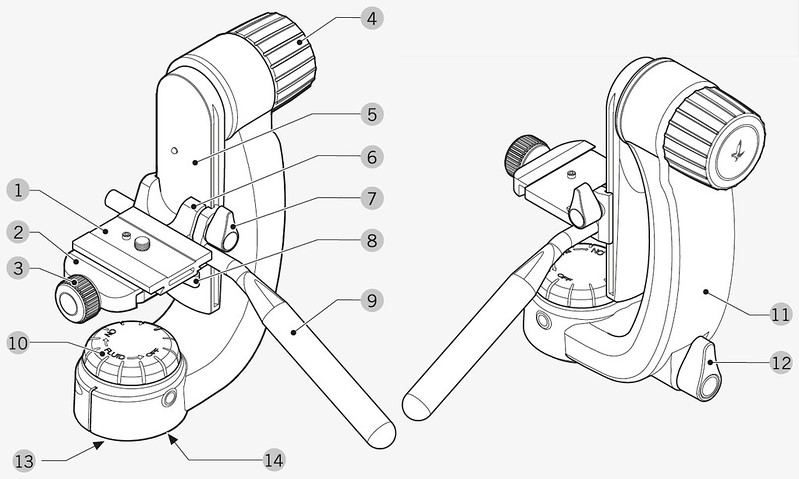

01 Connection plate - 3/8" connector thread (standardised)

02 Locking bolts - for attaching tripod head

03 Central column (external diameter 28 mm)

04 Clamp lever - central column

05 Limit stop - central column with 1/4" connector thread

06 Locking button for leg expansion - 3 angles of inclination

07 Quick locking clamp - for leg sections

08 Adjusting tool - quick locking clamp (CT 101, CT Travel)

09 Shoulder pad

10 Hook - removable

11 Spikes (AT 101)

12 Carrying belt - removable

13 Adjusting screws - for tripod leg movement

...I needed to Photoshop a Connection Plate onto the top of the Center Column because no stock photos were available. And the Connection Plate is off of a PCT and a lot thicker.

Much more accurate illustration from the Manual:

02-01313-C1

And a low resolution photo on the side plus a crop from Swarovski's PTH video below in which they're mounting on a CT101.

(And it looks like B&H...

http://live.staticflickr.com/65535/51348396937_5357681a52_o.png

...also had a hard time finding a stock photo of the CT101 minus a head.)

Pretty good additional smoking gun evidence of what a total joke Tripod/Head set screws are. If we tighten them evenly we start establishing a wave pattern in the Connection Plate. Thus if the set screws were serving anything beyond a placebo function they wouldn't/couldn't be.

And - speaking of locking things such that they won't rotate - the CT101's Center Column Clamping Lever won't/can't clamp the Center Column to the extent that it will prevent rotation. (Hell, it's essentially an M08-1.25 set screw installed such that it - in addition to not being able to solidly clamp anything - isn't able to damage anything.) The Gitzo clamping mechanism... no problem.

On the first outing of the Scope's first ecotour (Alaska) a glued on Foot fell off of the end of one of the CT101's Legs and was temporarily lost in the SUV's boot - an issue which took the whole Tripod out of action. (Good thing I'd purchased and packed a spare.) And about midway through the Scope's second ecotour (Costa Rica) there was a failure of the connection between the Connection Plate and the Center Column which critically and severely endangered the entire PTH / Balance Rail / ATX Scope assembly.

The Center Column is 28 millimeter aluminum tubing. The Connection Plate is mostly a piece of molded plastic with a 10 millimeter "long" finely threaded plug which is screwed and glued into the Center Column. If (When) that connection fails:

- the Center Column / Connection Plate component (it's considered a single component) is considered broken and must be replaced

- everything that's being supported by the Tripod is at a high risk of going into freefall mode

I was - luckily (as the CT101 is out of production and can no longer be supported) - able to obtain under warranty an intact Center Column / Connection Plate assembly replacement and restore my primary CT101 to its out-of-the-box condition. But that was the condition which at one point put five and a half thousand dollars worth of optical equipment at extremely high risk of toppling. And I would no longer use for my full assembly one of these Tripods for anything but an emergency backup. Substantially lighter loads... OK, but keep an eye on it. Based upon my experience with this issue there should be about zilch chance that we'll lose the Scope immediately after the component failure. Just don't push your luck after you've detected the wobble.

A PCT or Gitzo GT3542L Center Column will fit and work - but would be an exercise in throwing good money after not so good money.

---

2021/07/14 - I think I FINALLY figured out the whole story behind the CT101 Center Column failure - and it's pretty freakin' outrageous. Well, a little more freakin' outrageous than having a rather new and never even slightly abused Center Column fail for any reason in the first place.

I own two CT101s and three of their Center Columns:

- CT101-1 failed

- CT101-1 replacement

- CT101-2 original and pristine

Everything that can be seen - with CT101-1 insecurely reassembled - is identical. So that's a pretty good indication that all CT101 Center Columns are identical and this wasn't just an unfortunate one-off failure of manufacture and/or quality control.

Tubing is aluminum, everything in millimeters - OD 28, ID 26, Length 400, Threading (top and bottom, Connection Plate and Limit Stop) 1.00 (internal). Limit Stop is removable, Connection Plate is permanently glued in so we can't see anything until after it fails. Top end is cut square. Bottom is beveled.

Connection Plate and Limit Stop bodies are plastic. (Do we really need to be investigating much further?)

At the top squared glued end we have a range of 4 millimeters of smooth followed by 10 of threaded.

At the bottom tapered removable end we have threaded from IMMEDIATE and in to 11.

Between the Connection Plate flange and the beginning of the threading on its insertion cylinder (plug) - 5.0 millimeters of smooth followed by 7 millimeters of threaded. Between the Limit Stop flange and the beginning of the threading on its insertion cylinder - 2.5 millimeters of smooth followed by 6 millimeters of threaded.

Yeah, let's pull a number outta our ass and rate it for 5K grams - or about the same number of dollars worth of target glass - we're gonna load up onto it.

If any actual thinking of any degree went into any stage of the design and production of this equipment then all of these Center Columns are fabricated upside down with regard to the original intent.

The only ID we find on these Tripods...

- "SWAROVSKI OPTIK" on each of the three black foam rubber padding tubes on the three top Legs sections

- Decals:

-- "CT 101" on the Spider face between Legs 04 and 08

-- "Made in China / Fabriqué en Chine" well concealed on the top inside of Leg 08

And I'll bet they do a good job of wiping the fingerprints from all the relevant surfaces before shipping to the user.

---

From B&H:

Translation... Sucks for serious equipment. Agreed. Put a DH101 Head on it, use it for your binocular, keep an eye on things.Swarovski's CT 101 Carbon Fiber Tripod Legs feature a user-friendly lightweight (3.21 lbs/1.46 kg) construction, fast and almost soundless opening and closing of the leg retaining clamps, and a load capacity of 11 lbs (5 kg). With stable, low-maintenance, vibration-damping synthetic components made from Makrolon, these legs combined with a lightweight head (not included) are ideal for long hikes or travel with scopes or lightweight camera equipment.

- Sturdy, feather-light tripod with maximum carrying comfort

- Ideal for longer hikes, trekking, travel or digiscoping with lightweight camera equipment

- User-friendly ergonomic design

- Fast and almost soundless opening and closing of the leg retaining clamps

- Stable, low-maintenance, vibration-damping synthetic components made from glass fiber-reinforced Makrolon

- Supplied as standard with additional adjustment tool for locking legs

By the way... User-friendly? Name anything on any of these systems that isn't at least being presented as being user-friendly.

In my experience a tripod with a glued-on Foot which falls off and is lost for a day or two on a really serious expedition and a plastic glued-in lightly threaded connection plate which comes unglued and strips on another really serious expedition is as user-hostile as anything we wanna name. Ditto for the Gitzo/Swarovski upgrades with all of their pain-in-the-ass to nightmare issues. We want user-friendly these days we start looking at an ATX 49901 Objective / 85 millimeter 48885 Ocular combo for $4.1K - but then we realize there's no finder scope. So good freakin' luck.

---

But anyway...

We've designated the Leg counterclockwise from (in the illustration to our right of) the Clamping Lever as 12. It's also clockwise from the steel Eye Strap intended as the top anchor for the shoulder strap (that I suspect no one ever actually uses). And on the Spider between 04 and 08 we have nothing.

Leg pivot resistance is adjusted/set by adjusting torque on the Pivot Screw driven using a Torx 25 bit. They come from the factory torqued up about as hard as they can be. Maybe back off a wee bit then don't worry about it. Not a particularly critical issue on this tripod.

The CT101 includes a small tool which stows in neatly and fairly flush in a recess of any one of the three (identical) Level 1 Leg clamps. It's mostly a 3 millimeter Allen key 'cept the tip of the long end of the L lets it double as a slotted screwdriver. (See "SetScrews-CT101" above.) And the long end tip works fine in the Allen socket to spin things in at light torque. Note that when fully inserted the flathead screwdriver tip portion projects out through/low close to two millimeters. The "problem" though is fixed whenever we do full collapse.

The CT101 uses Extension Clamping Levers to lock, moderately clamp, free the six Legs Extensions of the Tripod. And the available clamping power for each Clamp is adjusted/set by turning with the aforementioned tool an M04-0.70x23 screw (same for both Levels) - exposed when the Clamp is swung open/loose. But don't assume that that we can do a one time universal tweaking operation and stay good - they seem to be a lot more temperamental than that. (Temperature sensitive?) So check and adjust as/if needed.

Tuning procedure...

- Pull the Center Column and set up (normally) with all three Legs fully extended and spread.

- Stand between Legs 04 and 08 and tilt towards 12 to bring it to vertical and 04 and 08 airborne.

- Hands on the Spider and/or Leg 12's Level 0 Tube (which is padded), press down HARD to try to induce a partial collapse. If you're:

-- successful identify the weak link, open the relevant clamp, tighten the adjusting screw no more than an eighth of a (clockwise) turn and retest

-- unsuccessful open the Level 2 (lower) clamp, loosen the adjusting screw an eighth turn, retest. If you're:

--- still unsuccessful keep going

--- successful tighten as per above and go up to Level 1

- Rotate clockwise and repeat for Legs 04 and 08.

For subsequent checks give anything that slips another eighth turn.

The thought occurs to me that these "Quick Locking Clamps" actually aren't - in actual practice. They require more manual precision, time, effort to operate and what should be a one-time-only resistance adjustment doesn't seem to be. I'm finding the PCT/Gitzo Twist Locks approach a much more practical and effective - not to mention robust and versatile - solution.

And note that in order to free the CT101's Clamps we need to work a thumb under the tip and lever it open. That can be substantial stress and I'd recommend going Level 2, Level 1 - rather than both simultaneously - for each pair. (But we can safely squash them both simultaneously with the heel of our palm for breakdown.)

Setup and breakdown actions are analogous to those described for the PCT.

ODs for Levels 0, 1, 2: 28, 24, 22 millimeters.

---

2019/05/11 - Found the Limit Stop (plug at the bottom of the Center Column) totally welded in place - despite the fact that I'd last installed it and wouldn't have gone nuts with force. Remove the Hook, boil a small glass of water in the microwave, immerse... End of problem.

2019/12/02 - For both of these CT101s I had to do the boiling water trick and use a rubber Jar Lid Gripper Pad. Lubricate the threads and be conservative with torque when reinstalling.

----------

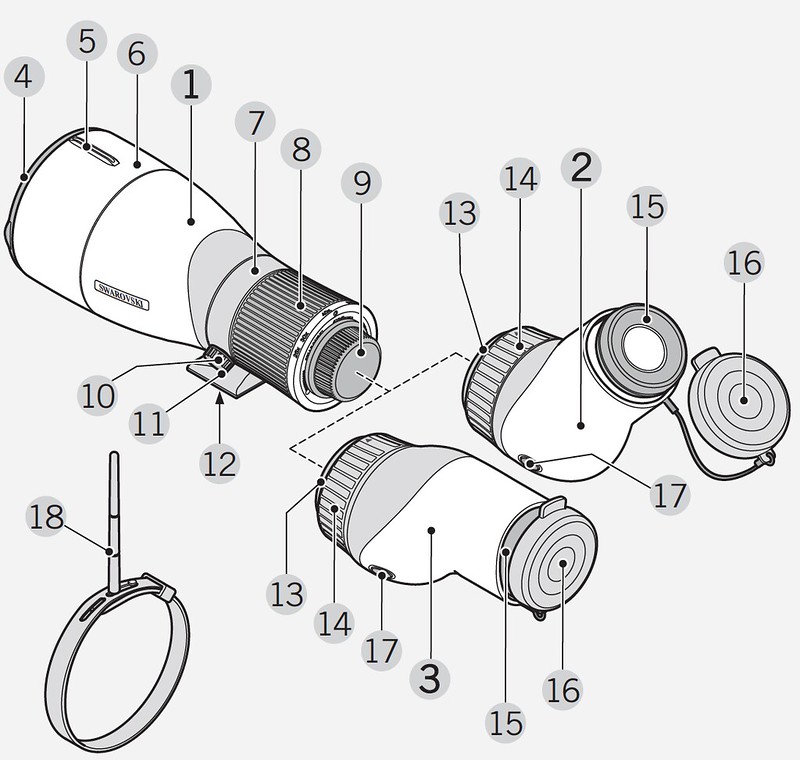

Gitzo PCT - Professional Carbon Tripod

http://aa.swarovskioptik.com/download/pdf/5475051-BA.pdf

(Note that back for the CT101 we had a "Central column". Not all that fluent in English and too goddam lazy to check.)

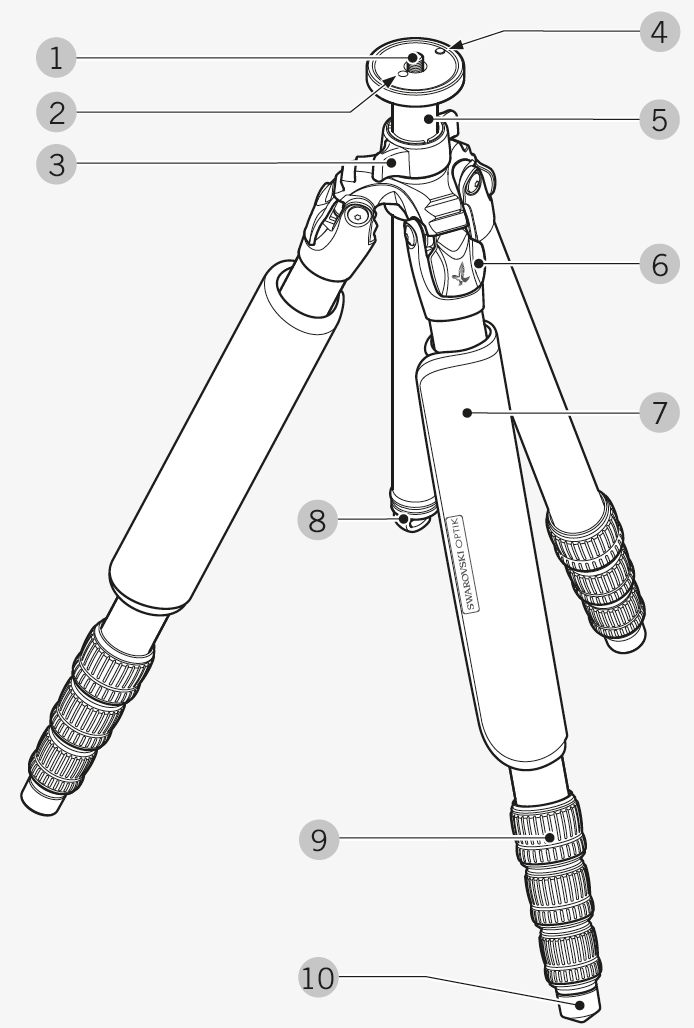

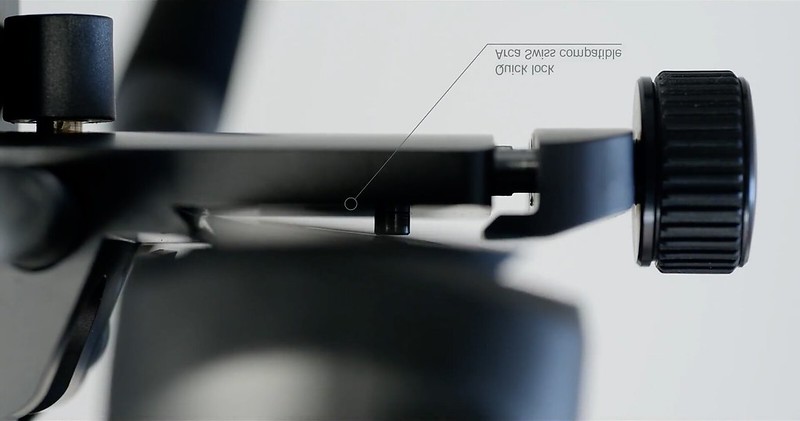

01 Connection plate - 3/8" connection thread, adjustable to 1/4" connection thread

02 Locking screw - adjustable connection thread

03 Lock lever - center column

04 Locking screw - for attaching tripod head

05 Center column

06 Locking knob - for setting angle of legs

07 Shoulder pads 2x

08 Hook - detachable

09 Screw cap - leg sections

10 Rubber feet - detachable

The first time I checked Swarovski's website after returning from Alaska I found my CT101 Tripod had been superseded by a "PCT - Professional Carbon Tripod":

http://c2.staticflickr.com/2/1775/43919904991_22a5bda4e7_o.png

http://live.staticflickr.com/65535/32932167597_6671ffae4e_o.png

46 pound load capacity versus 11, 5 centimeter higher full extension height, Feet are solidly screwed in (rather than being lightly glued on), collapses to 3 millimeters longer, a bit over 0.4 kilograms heavier, a few more bells and whistles, not far below twice the price... And apparently overnight they never heard of the CT101 before. No archives, Owner's Manual available. Pretty sure if we needed repair, parts, service we'd be SOL. Not impressed AT ALL by that bullshit. Making previously posted information unavailable to owners, customers, the public...

---

2019/03/13 - Update/Expansion on the PCT...

On 2019/02/07 I acquired a PCT.

I'd been assured that its Center Column wasn't compatible with the CT101 but guess what. Carbon versus aluminum, a bit shorter, but identical OD - 28 millimeters. Popped right in, really robust mounting for the Connection Plate...

...problem solved. I was not happy.

Didn't really wanna send it back though so spent a week studying, playing with it in an effort to justify the purchase of the whole freakin' assembly.

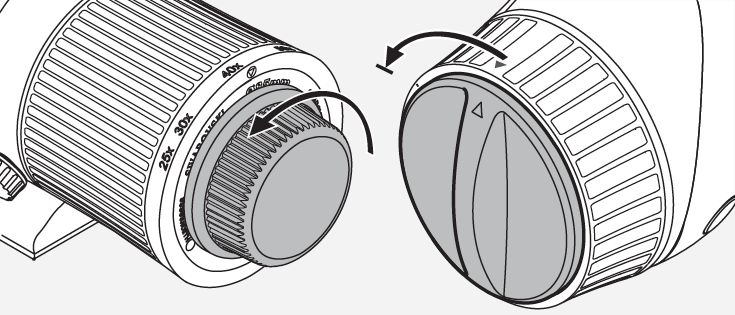

Four Leg sections - one fixed, three extendable (versus the CT101's three total). ODs: 33, 29, 25, 22 millimeters. Lock/Unlock by means of twisting Twist Locks rather than flipping (on/off) Extension Clamps.

The lengths of the Twist Locks are 38, 37, 36 millimeters for Extension Levels 1, 2, 3 respectively.

The Stops engaged by the Sliding Stop set our Legs angled out at 24-52-85 degrees. (And let's see what happens when we use this Swarovski label tripod at the 85 Stops... Spider near all the way down with Center Column all the way up.)

While the Center Column Lock Lever does cost us some squash range - as well as a little altitude over max stability potential - it is superior to the analogous arrangement on the CT101. Way more mechanical advantage and thus we can more quickly and easily achieve or undo a solid lock.

We won't be able to see it in any Swarovski photos or illustrations but there's a Ridge-and-Groove arrangement between the Center Column and the Spider Cylinder through which it slides. The Center Column has a deep Groove running its length and there's a metal projection low inside the Spider Cylinder - 12 millimeter vertical and about 3 width - which engages it and prevents the Column itself from yawing/panning when unclamped save for two or three degrees of slop.

Make a practice of centering the Groove over the Ridge with every clamp 'cause we'd rather not have any significant load on the materials in that area. What this feature does for us is keep us reasonably well on target when we have cause to extend or retract the Center Column. And if we're always shooting for center we'll be staying in pretty good shape.

2019/05/26 - Here it is on the one with the original Gitzo label:

Note the arrow indicator on the lower Spider area between 04 and 08 aligned with the Groove to help get us properly oriented for re-insertion. (None of this exists in Swarovski World.) Also:

- if we're not seeing the logo we're in good shape

- in lousy light we can feel for the arrow on the outside or projection on the inside

In no Swarovski promotional photo will we find the slightest indication that this Ridge-and-Groove feature actually exists. Ditto for fifteen relevant illustrations in the Owner's Manual - including, astonishingly, these two:

Must've been deemed insufficiently elegant.

Note that, while a PCT Center Column is compatible with a CT101 Tripod, the Ridge projection in the PCT negates the converse arrangement. But one really wouldn't want to go for the former anyway save for in some emergency situation.

---

The Swarovski flavor of this Tripod comes with two velcro-on Shoulder Pads which get installed around the uppermost reaches of the uppermost Leg sections. Their photo shows them installed on 12 and 08, their Owner's Manual shows them installed on 12 and 04, I had installed them on 04 and 08 before understanding how problematic they were and pulling them. (Funny Swarovski doesn't mention any issues.)

Issues... The Pads:

- prevent 08SW and 04SE from swinging/stowing together as well as they might otherwise - 'specially installed in conjunction with the Gitzo Level. This presents a bit of an issue when collapsing as described above. Minus the Pads the Legs fold in beyond parallel - to the point that at full extension the Feet are just a bit shy of being in contact with each other. And that works real well with what's involved in setting up vertical on an incline.

- present a lot more sail area way up as far as we can go - and where we least want it.

- are a pretty much unmitigated disaster.

http://live.staticflickr.com/65535/49323628837_321592d22b_o.png

2021/05/21 - According to their current Owner's Manual the tripod still ships with the Pads but otherwise good luck finding a current Swarovski illustration which includes them.

---

There's an O-Ring installed on the Ballast Hook plug (on the bottom end of the Center Column). Its purpose is to prevent hard contact between the metal plug and the three uppermost carbon Leg sections when the Tripod's folded. Unseats pretty easily. Lose it before you lose it. We need to install a Gitzo Center Column Bubble Level (see below) on the bottom end of the Column anyway and that provides a broad plastic contact surface / bumper just above the O-Ring and pretty much eliminates it from the equation.

If we lose the O-Ring and wanna lose another one just like it... Metric - 25 millimeter ID, 31 OD, 03 diameter. True Value sells it as a 98279.

There's another O-Ring installed around the base of the Ballast Hook's 12 millimeter diameter installation screw - for waterproofing I'd guess. 09 millimeter ID, 12 OD, 01.5 diameter.

Note that with the PCT in stock configuration with its Center Column fully extended the inward travels of the bottom ends of the fully retracted Legs are limited by each other. With the Gitzo Center Column Bubble Level installed we lose 9 millimeters worth of extension and the 30 millimeter max OD of the (hard metal) Ballast Hook component limits the inward travel (against tons worth of mechanical advantage). This is not a good situation but one unlikely to be stumbled into inadvertently. With the Center Column fully retracted - as it should be - the Bubble Level OD is the limiting factor and the retracted Legs fold in to a bit inside of parallel to each other.

http://live.staticflickr.com/65535/32932167597_6671ffae4e_o.png

---

The Legs pivot out/in on an axle (D104217) secured by Torx 25 head M06-1.00x13 screws at both ends up at the Spider (D104201C30Z).

Torque target should be:

- Leg fully extended and angled up/out to horizontal

- stays that way save for a small fraction of a degree

Rock solid leaves us with excessive stiffness which does nothing but work against us during routine ops. For the instructions on working on this connection see the "Tools" section.

---

2023/06/01 - Couple days ago I experienced an incident with my primary Mountaineer flavor Tripod near the beginning of a practice/solar set.

GitzoSystematic-3

http://live.staticflickr.com/65535/52886174732_3a62354ab1_o.png

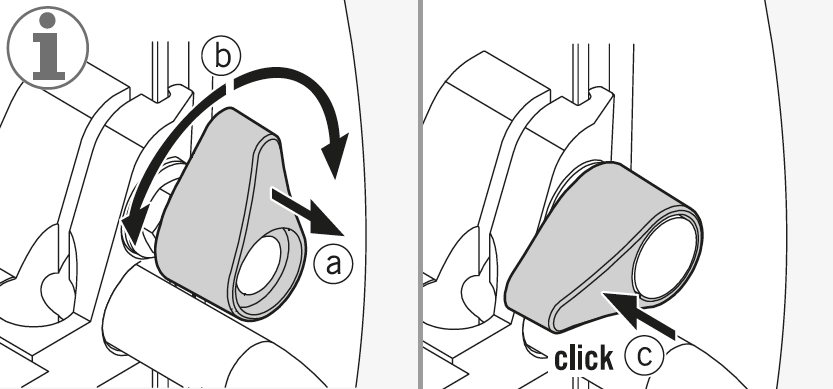

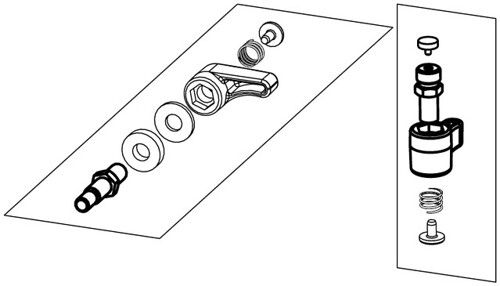

There's a very cleverly engineered spring loaded three part component outboard of the pivot point at the top of each Leg which - when tripped and engaged - arrests the Leg's pivoting out at the 24-52-85 degree stops when the stops are engaged.

http://www.manfrottospares.com/image/cache/catalog/D1/d104211z-228x228.jpg

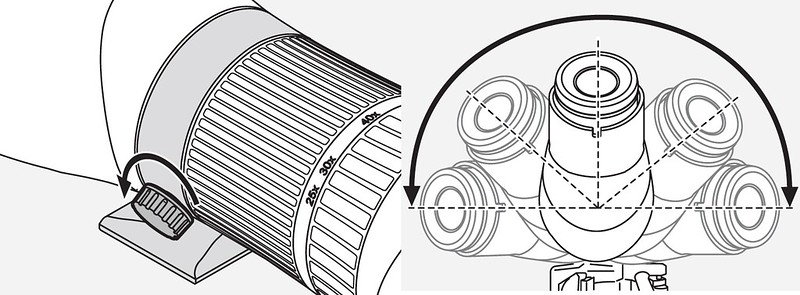

Gitzo refers to it as a D104211Z Assembly Square, Swarovski as a Locking Knob. Pull/Disengage it and the Leg can be angled out to 90. At that point the D104211Z is automatically tripped and re-engages as we're angling back in/down.

There's a:

- main structural component

- special machine screw

- trapped spring

Screw's overall length is 14 millimeters and diameters of regions from head to tip are 7-5-4-3. Corresponding depths are 3-4-4-3.

- Head is pan with a 3 millimeter hex socket.

- Clear shaft engages the Spring coils - and nothing more.

- Threaded shaft is M04-0.70.

- Tip projects down into a narrow box canyon channel and prevents the assembly from exiting outboard in one's hand.

The Spring is symmetrical - rightside up is identical to upside down. It's ends are tensioned together towards outboard and seated in the recesses of the top of the Zero level component of the Leg at the same level.

The Screw had backed out to the extent that its tip no longer projected down into the channel and when I pulled the Knob the assembly exited outboard in my hand.

With the Leg angled out and locked at the 52 stop we have an excellent shot at the head of the Screw. My 3 millimeter Allen key's short/business leg is under 20 millimeters. That leaves us tons of clearance below and inboard of the axle. I don't know if it's possible/practical to reinstall the D104211Z after separation with the Leg installed - what with spring issues - but it's brain dead easy to screw in and torque up before getting to that point. Occasional visual inspections and retorqueings will serve us extremely well.

---

Pack for the next stop or plane, fully collapse and stuff the assembly in the same 34 inch Benbo Trekker Tripod Case that we use for the CT101 with the PTH (also) installed. According to the Manuals, CT101 and PCT collapsed lengths - 58 and 56 centimeters respectively. If one actually measures them however, one gets about 58.1 and 58.4 respectively - not to mention another 7.5 millimeters for the Head Mounting Stud projection.

---

2021/05/21 - Acquired and test drove a Gitzo GT3542L Mountaineer Tripod. Impressions, observations...

At 21 percent over the Swarovski label PCT - which includes the Shoulder Pads and Strap nobody ever actually uses and/or wants and whose production is environmentally irresponsible - it's overpriced. But give them a wee bit of credit for including stuff the owner is likely to use. Three key tools - a pair of Torx 25s and a 3 millimeter Allen.

Each Foot includes a spring which wraps around the bottom region of the Foot's installation screw and is compressed when the Foot is screwed into its receptacle. Probably prevents the Foot from backing out during normal use and that does seem to be an issue on the PCT - but not enough to be concerned about losing a Foot and it's a good and easy practice to give each Foot a quick clockwise twist when stowing anyway.

I'm finding that I need to REALLY torque the Twist Locks to get the Extensions firmly locked at target - 'specially (not surprisingly) the Level Threes. Can't understand why 'cause - aside from one or two cosmetic only issues - the components are identical. Maybe/Hopefully a break-in issue.

The Gitzo label features some engineering which permits one to truncate the Center Column down to a stub...

http://live.staticflickr.com/65535/51193806403_feb8288ab4_o.png

http://live.staticflickr.com/65535/51193592776_2c97e0d0a3_o.png

...to configure for a "Ground Level Set" in which the Legs are spread way out to a bit shy of ninety. At max spread we get 68 millimeters worth of projection below the bottom rim of the Spider's Center Column Cylinder.

http://live.staticflickr.com/65535/50939065262_d7e70d9d13_o.png

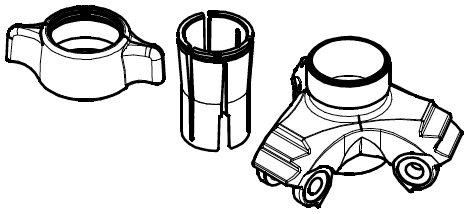

The stub center column extends 31 millimeters down into the Spider's 57 millimeter depth Cylinder and normally fits over the top end of the main Center Column tube. There's a Ground Level Set Ring which:

- is left hand threaded and makes things a bit confusing as one is gearing up

- serves to lock itself and the rest of the Connection Plate assembly to the main Center Column tube

To go forth and back to and from Ground Level Set....

- Unclamp the Center Column and reset and clamp the assembly just high enough above the Lock Lever to be able to see and align the Groove on the main with the alignment mark on the stub.

- Spin the Ground Level Ring full bird's-eye-view counterclockwise to allow separation or full engagement and seating of the two components.

- Separate or fully engage and spin the Ground Level Ring full bird's-eye-view clockwise to lock.

- Proceed to effect and enjoy the desired mode.

This is a trick one would ONLY wanna employ for photography / NEVER wanna employ for scope/observation stuff.

Cost of having the full Mountaineer Center Column assembly on standby:

http://www.manfrottospares.com/

Manfrotto Spares and Parts

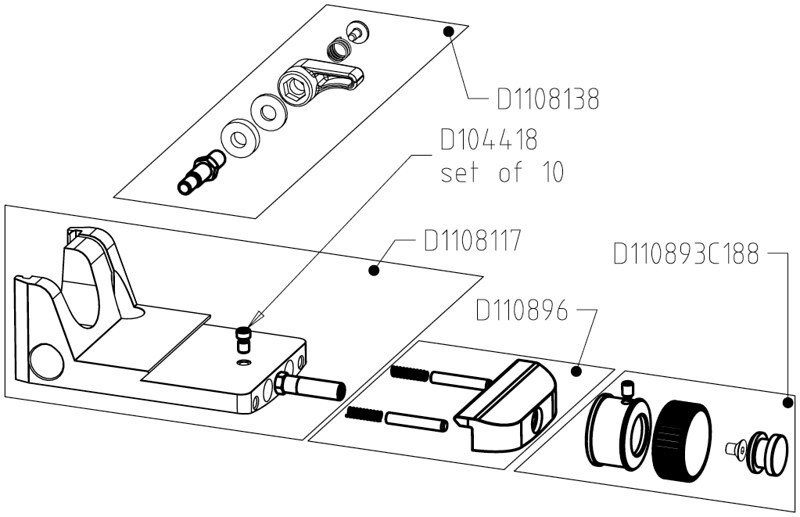

015.66 - D0702.01 - Insert

055.40 - D104215 - Assembly Disc

120.14 - D104208 - Disc

167.82 - D107001 - Assembly Column

031.41 - D104214 - Ballast Hook

390.43 - Total

Plus shipping. (And a Bubble Level.) But we got the "Swarovski" PCT for two hundred bucks under.

Or we could just do the first/top three components and have the assembly we'd actually be using for a Ground Level Set.

Kinda interesting the way Swarovski has eliminated the Ground Level Set capability from their flavor of the Gitzo Mountaineer Tripod given that their ATX/STX Scope line is engineered as a digiscoping platform.

(Also a bit interesting to note that if the ground upon which we're ground level setting isn't level then we have no way of getting whatever it is we have installed in our spider solidly vertical without getting a bit creative.)

---

2023/01/07

And now that Swarovski would be pretty happy having everybody forget everything about their ATX/STX Scope line having been engineered as a digiscoping platform they're about as interested in Ground Level Set capability as Yours Truly is.

A spotting scope is designed for spotting and observing. The purpose of a camera is to record images. Gear up and operate accordingly.

---

On about 2021/07/12 I had a rather unpleasant and probably expensive learning experience involving my less than two month old Gitzo GT3542L Tripod and first PTH Head.

With the Swarovski flavor of the Tripod I can lock the Head down (as I've described below) by clamping the Center Column and Head to max pan resistance torqueing the Head clockwise to near the limit of my physical capability. And I still believe it's virtually impossible to cause an overload of anything with this technique. With the Gitzo Ground Level Set capable model however... SNAP and I heard a small chunk of metal fall inside the length of the Center Column.

When I pulled the Ballast Hook the small chunk of metal turned out to be the lower 6 millimeters of what used to be a 3 millimeter diameter and 14 long steel Dowel Pin. It fits in the notch in the fitting at the top of the regular Center Column - which we'll designate as the Center Column Plug - we can see illustrations above. And with it sheared what's left at the top can't be clamped hard enough to permit separation of the Head from the top end mounting stuff.

I'm sure that if I didn't care about further mangling the top end mounting stuff I could get the Head free with a pipe wrench but I do and will see if some local machine shop has some large sorta chuck to do the job right. Then they might ever be able to extract what's left of the Pin and tap in a replacement.

Not really pissed off at myself over this one. We need a lot of torque to make sure we won't back the Head loose with counter panning, this rig is under-engineered, there was no caution in the fuckin' manual or any other advisory. In the Spider Cylinder there's a 12 millimeter long (high) Ridge with a 3 millimeter width at its base which engages the Groove and prevents rotation and it doesn't fail. Should've been engineering up top with comparable capacity.

--

2022/12/13

We DON'T NEED and should NEVER USE anything but minimal torque to mount ANY head but good freakin' luck finding the issue dealt with in any fuckin' manual or manufacturer's instructional video. In "Video Tutorial Set up and features of the SWAROVSKI OPTIK PTH professional tripod head" for example the head mounts itself on the tripod and has the set screws engaged with no human intervention whatsoever. Maybe we could get more information on the subject by watching "Video Tutorial Set up and features of the SWAROVSKI OPTIK ATH amateur tripod head".

See this date's entry below in the "Head Installation" discussion.

--

And we're screwing onto a 3/8 inch / nine and a half millimeter diameter Stud but preventing rotation with a three millimeter diameter Pin? Yeah, the Pin's out from center about ten and a half but still...

This issue should be covered under warranty but I've read enough pissed off reviews regarding service from these folk that I won't bother.

When I get back in business I'll need to develop a sweet spot hitting skill.

---

Got my self and wreckage into Covington Machine & Welding in Annapolis. Guy (his name) came to my assistance, got kinda interested as I explained the problem. Ran back out to the car to get the Swarovski intact versus Gitzo out-of-commission assembly to show him how things were supposed go together and come apart. He was worried that he might have to mangle the Stub Column of the D104208 Disc in clamping it sufficiently but had things apart and unmarred in no time. Then, with the separation issues resolved, he tapped out the upper 8 millimeters of the Dowel Pin through the upper surface of its component. Couldn't replace it 'cause he didn't have the material but I was pretty happy. And he wouldn't take a penny for his time and effort.

But the bad news... Undetectable visually but the Stub Column must now be ever so slightly out of round. Reinsert the Center Column Plug of the D107001 Assembly Column. Takes lotsa effort. And when one pulls it back out the resistance is so high that the Plug comes unglued from the carbon column tube.

For want of an adequate Dowel Pin the D104208 Disc was lost. For want of a fully intact D104208 Disc the Center Column was lost. I can still mount a Scope and have everything reasonably functional. And I'm safe as long as things don't get turned upside down - and that's something that never happens with me in the field. But now what I have is something of a pristine looking and very expensive garbage dump. One thing Swarovski seems to have gotten right on this one.

---

2021/07/28 - Had ordered a D1318.25 Center Column from Manfrotto Spares. Big mistake. Works for the installations at top and bottom end, 115 millimeters longer - still OK... Diameter 32 versus 28. If I'd been smart enough to compare these two images:

http://live.staticflickr.com/65535/51341429281_0dbbd7f544_o.png

http://live.staticflickr.com/65535/51342169579_39b2d76d2d_o.png

GT3541L and GT3542L side by side the fatal flaw would've been obvious.

(All the other carbon tubing sections and Twist Locks are the same. The 2's Legs appear more robust 'cause it's "shorter" - the Center Column isn't extended nearly as high as the 1's - and it's shot from closer or zoomed in more.)

---

http://www.bhphotovideo.com/c/product/1034917-REG/gitzo_gt3542l_gt3532_mountaineer_series_3.html

Gitzo GT3542L Mountaineer Series 3 Carbon Fiber Tripod GT3542L

Yeah.JonH - 2016/06/16

Verified Buyer

Nice tripod, poor quality, worse service

My GT3542L was two months old when the center column failed. The previous one I ordered from B&H also failed, but B&H nicely replaced it. The Manfrotto/Gitzo service facility in AZ (CRIS (Camera Repair Instrument Service)) has had my tripod for 3 weeks. They never acknowledged receipt, gave me a time frame, or communicated with me in any way. I've called them multiple times, and they referred me to Manfrotto in NJ. A ship from Italy (I kid you not), is arriving in one week with the part for my tripod. I think. They couldn't tell me for sure except that a center column for a tripod model # same as mine was arriving in a week. So if that is even FOR my tripod, the CRIS facility will have had my unit for well over a month. Stay away. I am looking into RRS or FLM, and trying to find out now about their service. Nice functionality, horrible quality and terrible customer service.

But living with the wreckage - everything failed and disconnected to the extent my Center Column assembly is...

Shove everything back together so it at least looks like it did coming out of the box - same overall length (height - actually) - minus the Ballast Hook (and Bubble Level) for the time being. Measure up 272 millimeters from the Center Column's bottom end and pencil mark (in the face of the Groove area where we'll be able to see things). Install the Center Column down into the Spider's Cylinder and hard clamp such that our mark appears below / just clear of we'll have 272 millimeters of Center Column extending below the Cylinder. When we're hard clamped with that extension we'll have the Shim engaging enough of both the Center Column and D104208 Disc's Stub Column totally immobilized.

If we pan the Scope counter enough continuous revolutions we can disconnect it from the Stud and drop it but otherwise we're perfectly safe and reasonably functional.

---

2021/08/07 - Got an eBay 3x14 millimeter steel Dowel Pin from Nanjing in today's mail. Got fifty of them actually - though I just asked for two (and the dickhead agreed). (Also some 4x30s for my Lens Support Clamp modification.) Easily tapped back into the D104208 Disc and restored my ability to torque a Head back on with the same degree of security allowed by this Center Column just outta the box (for all that that's worth). With the Center Column raised a wee bit up from min the only thing keeping the Scope assembly connected is gravity but that's a reasonably reliable force down here on the planet's surface. I think I'll be able to hot-glue the Center Column's top fitting back into place as securely as it was originally. Then all I'll be down in functionality will be the lack of Ground Level Set capability. And that I can continue living just fine without.

---

2021/08/09

In the top of cylinder of the of the D104208 Disc's (silver) Lock Wheel there's a Retaining Ring. ID and OD are a bit over 35 and 37 millimeters respectively, round cross section. It can be disengaged and removed with an index fingernail. Do it so's we can see how this thing is put together and works.

First off... All the Retaining Ring does is restrict the Lock Wheel rotation to what's required to enable disengagement of the Center Column. We could live without it easily enough.

Let's do the next steps with our D104208 Disc assembly standing upright on a tabletop.

The Lock Wheel engages the (black) Stub Center Column by means of about seven threads worth of left 35-1.25 millimeter near the tops of both main components. So keep things vertical and spin the Lock Wheel counter down the Stub Column a bit over four revolutions until we're disengaged and pull the Stub up and out clear of the Wheel. Stay vertical and set it back down.